Conclusions

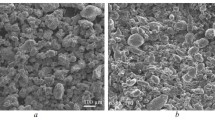

A necessary condition for improving the magnetic properties of powers is improvement of the metal phase structure, elimination of nonmagnetic impurities, and destruction of a chemisorbed coating. Annealing in hydrogen at 633–653 K makes it possible to retain the main geometric size of particles within the limits 0.8–1.0 Μm, to reduce dendrites and to increase the coercive force by a factor of 1.5–2 and the residual specific magnetization of iron and Fe-Co alloy powders up to 95 and 105 A·m2/kg, respectively.

Similar content being viewed by others

Literature cited

V. V. Nepomnyashchii, L. N. Tul'chinskii, E. P. Zhelibo, and L. B. Strashinskaya, “Reducing anneal for highly dispersed electrolytic iron powders with an organic coating for particles,” Poroshk. Metall., No. 7, 1–7(19820).

E. P. Zhelibo, “Corrosion of highly dispersed electrolytic iron powders,” Poroshk. Metall., No. 6, 4–9 (1982).

E. P. Zhelibo, T. M. Shvets, T. I. Amelichkina, and V. V. Nepomnyashchii, Inventor's Cert. 956627 USSR, “Method for preparing highly dispersed magnetic powders,” Otkrytiya. Izobret., No. 33, 259 (1982).

I. N. Frantsevich, L. N. Tul'chinskii, T. M. Shvets, and V. V. Nepomnyashchii, “Preparation of constant magnets made of highly dispersed iron and iron-cobalt alloy powders with an organic coating and studies of their properties,” in: Materials of the Internat. Conf. on Powder Metallurgy, Dresden (1977).

V. V. Nepomnyashchii, “Development of magnetically hard materials based on highly dispersed electrolytic powders,” Author's Abstr. Diss. Cand. Tech. Sci., Kiev (1986).

K. K. Ilyunin (ed.), Handbook for Electrical Measuring Instruments, 2nd. edn. [in Russian], Energiya, Leningrad (1977).

L. I. Mirkin (ed.), X-Ray Structural Analysis. Preparation and Measurement of X-Ray Pictures (Handbook)[in Russian], Nauka, Moscow (1976).

é. M. Natanson and é. R. Ul'berg, Colloidal Metals and Metals Polymers [in Russian], Naukova Dumka, Kiev (1971).

A. N. Pilyankevich, Practice of Electron Microscopy (preparation methods) [in Russian], Mashgiz, Moscow-Kiev (1961).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4(340), pp. 74–78, April, 1991.

Rights and permissions

About this article

Cite this article

Nepomnyashchii, V.V. Heat treatment of highly dispersed electrolytic iron and Fe-Co alloy powders with a composite coating. Powder Metall Met Ceram 30, 326–329 (1991). https://doi.org/10.1007/BF00795967

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00795967