Conclusions

Compacting by hydrostatic pressure of the powder blank preshaped by vacuum sintering to a density of 0.88–0.90 of the theoretical value makes it possible to obtain by hot pressing without a metallic sheath rods with circular and shaped sections with the density of the material close to 100%.

The properties of the hot-pressed high-speed steel of the 10R6M5-MP grade produced from powder blanks compacted by hydrostatic pressure without the metallic sheath are higher than similar properties of R6M5 steel produced by the standard method and are not inferior and, in some case, are even superior, to the properties of a similar steel quoted in literature sources and produced by hot gas static pressing followed by forging or hot extrusion of the powder in the capsules.

Use of the hot-pressed shaped rods without the metlalic sheath for producing cutting tools makes it possible to increase its strength 1.6–2.0 times in comparison with tools of 10R6M5-MP high-speed steel and the steel produced by the standard method. The coefficient of utilization of the metal may increase to 0.7–0.8.

Similar content being viewed by others

Literature cited

V. I. Trefilov, “Powder metallurgy at the start of 12th Five Year Plan,” Poroshk. Metall., No. 2, 3–6 (1986).

A. K. Petrov, Yu. N. Skorikov, G. I. Parabina, et al., “Properties of blanks of high-speed tool steel produced by hot extrusion of dispersed powder,” Poroshk. Metall., No. 9, 23–27 (1980).

V. B. Akimenko, A. A. Galkin, I. Ya. Kondratov, et al., “Production of blanks for cutting tools by hot extrusion of powder,” in: Hot Pressing [in Russian], Institute of Problems of Materials Science, Academy of Sciences of the Ukrainian SSR, Kiev (1973), pp. 116–119.

V. Z. Spuskanyuk, A. A. Lyadskaya, and V. A. Nifontov, “Hot extrusion of disperse powders of high-speed steels,” Fiz. Tekh. Vys. Davl., No. 11, 59–63 (1983).

A. A. Khamitov, V. K. Zamaraev, and B. N. Popov, “Effect of shaping conditions on the properties of extruded 10R6M5 powder steel,” Poroshk. Metall., No. 9, 9–12 (1988).

I. V. Vlasyuk, V. N. Klimenko, I. D. Radomysel'skii, et al., “Examination of methods of cold pressing charges of high-speed steels. Hydrostatic pressing,” Poroshk. Metall., No. 6, 16–19 (1973).

N. N. Talalueva, N. P. Chumakov, V. S. Tyutenko, et al., “Containers for investigations at high pressures,” Fiz. Tekh. Vysokikh Davl., No. 31, 87–89 (1989).

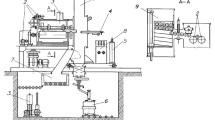

N. P. Chumakov, N. N. Talalueva, V. S. Tyutenko, et al., “Equipment for hydrostatic pressing components from powders of high-speed steels,” Fiz. Tekh. Vys. Davl., No. 31, 90–92 (1989).

B. I. Beresnev, V. Z. Spuskanyuk, V. S. Tyutenko, et al., “Compacting porous briquettes of high-speed steel in hydrostatic treatment,” in: Proceedings of 4th All-Union Conference on Hydrostatic Processing of Materials, Institute of Technical Physics, Academy of Sciences of the Ukrainian SSR, Donetsk (1985).

N. V. Manukyan, Kh. L. Petrosyan, and S. G. Agbalyan, “Examination of heat treatment of sintered high-speed R6M5 steels,” Poroshk. Metall., No. 9, 48–53 (1983).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 10 (346), pp. 17–21, October, 1991.

Rights and permissions

About this article

Cite this article

Spuskanyuk, V.Z., Tyutenko, V.S., Darda, Y.A. et al. Heat treatment and properties of 10R6M5-MP high-speed steel produced from gas-dispersed powder at high hydrostatic pressures. Powder Metall Met Ceram 30, 824–827 (1991). https://doi.org/10.1007/BF00795849

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00795849