Conclusions

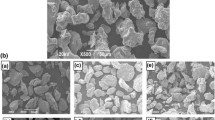

The thermal conditions of treatment of oxide powders produced by chemical coprecipitation exert a pronounced influence on the mechanical properties of semifinished products of dispersion-strengthened nickel made from these powders. Raising the calcining temperature of such oxide powders activates particle redistribution processes and has an adverse effect on the uniformity of distribution of the strengthening phase, which leads to the formation of large particles in the subsequent stages of plastic working and heat treatment of the powders and a steady deterioration in the mechanical properties of semifinished products.

Similar content being viewed by others

Literature cited

R. L. Graham, D. A. Edge, and D. C. Moore, “Dispersion-hardened copper and copper alloys made from chemically prepared powders,” J. Inst. Met.,99, No. 3, 81–92 (1971).

A. P. Gavrilenko, M. S. Koval'chenko, and É. T. Denisenko, “Production of dispersion-strengthened metals and alloys by powder metallurgy techniques,” in: Powder Metallurgy [in Russian], Latvian Institute for Scientific and Technical Investigations, Riga (1975), pp. 205–206.

K. I. Portnoi and B. N. Babich, Dispersion-Strengthened Materials [in Russian], Metallurgiya, Moscow (1974).

Ya. E. Geguzin and M. A. Krivoglaz, Motion of Macroscopical Inclusions in Solids [in Russian], Metallurgiya, Moscow (1971).

K. I. Portnoi, B. R. Gorobets, I. V. Romanovich, and B. N. Babich, “Relationship between the heat resistance and structural parameters of dispersion-strengthened nickel,” Poroshk. Metall., No. 1, 96–100 (1974).

I. D. Morokhov, L. I. Trusov, and S. P. Chizhik, Ultrafine Metallic Media [in Russian], Atomizdat, Moscow (1977).

K. I. Portnoi, B. N. Babich, I. V. Romanovich, and V. M. Romashov, “Growth of particles of strengthening phases in the processes of production of dispersion-strengthened alloys,” Fiz.-Khim. Obrab. Mater., No. 6, 99–103 (1973).

V. P. Buntushkin and A. I. Potemkin, “Rate of growth of refractory oxide particles in powder metallurgical nickel,” Poroshk. Metall., No. 7, 82–86 (1972).

B. N. Babich and I. V. Romanovich, “Effect of compact sintering temperature upon the structure and properties of dispersion-strengthened nickel,” Poroshk. Metall., No. 4, 29–33 (1975).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 8(236), pp. 43–46, August, 1982.

Rights and permissions

About this article

Cite this article

Babich, B.N., Fofanov, A.A. Effect of thermal conditions of preparation of dispersion-strengthened nickel powders on the character of distribution of the strengthening phase. Powder Metall Met Ceram 21, 637–639 (1982). https://doi.org/10.1007/BF00795519

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00795519