Conclusions

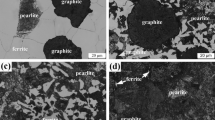

A study was made of the processing properties of a reduced ultrafine electrolytic iron powder. The key parameter determining these properties is powder reduction temperature, which controls also the density of finished parts. An investigation into the process of structure formation during the heating of compacts for hot forging demonstrated the feasibility of producing α-Fe of grain size 1 μm or less. The principal parameters determining the conditions of production of an ultrafine α-Fe grain are compact heating temperature and rate and duration of holding at the heating temperature. It is shown that ultrafine iron powders can be employed for manufacturing high-strength ultrafine-grained materials.

Similar content being viewed by others

Literature cited

V. S. Ivanova and L. K. Gordienko, New Ways of Increasing the Strength of Metals [in Russian], Nauka, Moscow (1964).

R. V. Armstrong, “Strength properties of metals with an ultrafine grain,” in: Ultrafine Grain in Metals [Russian translation], Metallurgiya, Moscow (1973).

V. I. Trefilov, Yu. V. Mil'man, and S. A. Firstov, Physical Basis of the Strength of Refractory Metals [in Russian], Naukova Dumka, Kiev (1975).

É. M. Natanson, Colloidal Metals [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1959).

E. P. Abrahamson, “Production of ultrafine-grained alloys by a controlled alloying method,” in: Ultrafine Grain in Metals [Russian translation], Metallurgiya, Moscow (1973), pp. 82–89.

W. Borland, J. P. Evans, P. G. Mordon, et al., “Effect of purity on sintering behavior and properties of iron compacts produced from fine powder,” Powder Metall., No. 3, 145–152 (1980).

V. V. Nepomnyashchii, L. N. Tul'chinskii, E. P. Zhelibo, and L. V. Strashinskaya, “Reduction annealing of very fine electrolytic iron powders with organic coatings,” Poroshk. Metall., No. 7, 1–7 (1982).

I. M. Fedorchenko and R. A. Andrievskii, Principles of Powder Metallurgy [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1963).

M. Paulus, “Ultrafine powders,” Plenary Lectures and Reports on Round Table Discussions of the Fourth European Symposium on Powder Metallurgy, Paris (1975), pp. 166–181.

M. L. Bernshtein, Thermomechanical Treatment of Metals and Alloys [in Russian], Metallurgiya, Moscow (1968).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4(280), pp. 1–7, April, 1986.

Rights and permissions

About this article

Cite this article

Dzyubenko, A.I., Lyapunov, A.P., Radomysel'skii, I.D. et al. Effect of reduction temperature on some properties of ultrafine iron powders and hot-forged specimens. Powder Metall Met Ceram 25, 261–266 (1986). https://doi.org/10.1007/BF00794399

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00794399