Conclusions

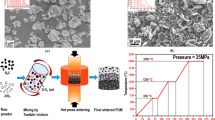

A study was made of the mechanical properties of materials produced from an ultrafine aluminum nitride powder. It is shown that use of such a fine powder enables virtually nonporous specimens to be produced having high strength characteristics: σc=1600 MPa, σtr= 320 MPa, microhardness of 16,800 MPa, microstrength of 3100 MPa, and microbrittleness of 1.9. On the basis of the results obtained it is possible to recommend aluminum nitride sintered from an ultrafine powder as a good-quality constructional ceramic material.

Similar content being viewed by others

Literature cited

D. N. Poluboyarinov, M. R. Gordova, I. G. Kuznetsova, and N. V. Zakharova, “Sintering of aluminum nitride ceramics,” Izv. Akad. Nauk SSSR, Neorg. Mater.,2, No. 1, 72–76 (1975).

D. P. Zyatkevich, Ya. P. Grabis, G. N. Makarenko, et al., “Manufacture of fine aluminum nitride powder,” Poroshk. Metall., No. 10, 1–5 (1977).

V. I. Torbov, V. N. Troitskii, and A. Z. Rakhmatullina, “Hot pressing and vacuum sintering of fine titanium nitride powder,” Poroshk. Metall., No. 12, 27–32 (1979).

O. V. Pshenichnaya, M. A. Kuzenkova, and P. S. Kislyi, “Effect of powder particle size on the sintering of zirconium nitride,” Poroshk. Metall., No. 12, 33–39 (1979).

M. A. Kuzenkova, P. S. Kislyi, G. N. Makarenko, et al., “Sintering behavior of aluminum nitride synthesized in low-temperature plasma,” Poroshk. Metall., No. 4, 25–29 (1978).

V. V. Skorokhod, V. V. Panichkina, Yu. M. Solonin, and I. V. Uvarova, Fine Refractory Metal Powders [in Russian], Naukova Dumka, Kiev (1979).

V. F. Berdikov, “Some key regularities of elastic-plastic deformation and brittle fracture during the microindentation of the surface layers of a solid,” in: Physics of Brittle Fracture [in Russian], Vol. 1, Kiev (1976), pp. 208–212.

V. F. Berdikov, A. V. Babanin, and N. I. Bogomolov, “Study of the mechanical properties of various abrasive materials in the grain by the microindentation method,” in: Abrasives [in Russian], Vol. 8 (1975), pp. 1–11.

G. V. Samsonov, Yu. G. Tkachenko, V. F. Berdikov, and G. A. Bovkun, “Microhardness, microbrittleness, and brittle macrostrength of transition metal carbides,” in: Carbides and Their Alloys [in Russian], Naukova Dumka, Kiev (1976), pp. 98–104.

V. F. Berdikov, A. V. Gur'ev, and G. V. Malovechko, “Automatic loading attachment with a damping device for the PMT-3 tester,” Zavod. Lab., No. 11, 1398–1399 (1964).

V. F. Berdikov, G. P. Zaitsev, and V. P. Shiryakin, “Accuracy of microhardness determination,” Zavod. Lab., No. 7, 856–860 (1969).

D. P. Zatkevich, P. S. Kislyi, T. Ya. Kosolapova, et al., “Structure and strength of aluminum nitride polycrystals,” in: Methods of Preparation, Properties, and Fields of Application of Nitrides [in Russian], Zinatne, Riga (1980), pp. 50–52.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 12(240), pp. 65–69, December, 1982.

Rights and permissions

About this article

Cite this article

Zyatkevich, D.P., Berdikov, V.F., Makarenko, G.N. et al. Mechanical properties of materials obtained from an ultrafine aluminum nitride powder. Powder Metall Met Ceram 21, 961–964 (1982). https://doi.org/10.1007/BF00794340

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00794340