Conclusions

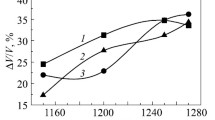

A study was made of the conditions of direct synthesis of composite MAMs from the simple substances. It has been established that the heating of mixtures of powdered carbide-forming transition metals (Ti, V, and Cr), carbon black, and iron in the temperature range 1300–2000°C results in preferential formation of titanium and vanadium carbides which are uniformly distributed in an iron matrix in the form of globules. The shape and size of the globules are determined by the carbide concentration in the composite and synthesis conditions. The chromium carbide Cr3C2 is not easy to synthesize in the presence of iron. The boundaries of fields of synthesized titanium and vanadium carbides in an iron matrix are clearly defined. The extent of carbide-iron interpenetration is negligible, not exceeding 3–7% of the carbide grain (globule) diameter. In the series Ti-V-Cr the degree of chemical reaction of these carbide-forming metals and their carbides with iron increases from titanium to vanadium and chromium. On the basis of data yielded by this investigation, a method is proposed for producing titanium carbide- and vanadium carbide-containing iron-base composite MAMs; the optimum compositions and conditions of synthesis of such composites have been determined. Pseudofused composite MAPs containing titanium and vanadium carbides possess excellent physicomechanical properties (grain strength, abrasive ability, and specific saturation magnetization intensity), and can be recommended for machining various materials, in particular steels. The results obtained have been utilized in the development of TU 6-09-4575-78 for MAMs, on the basis of which such materials are now being produced on an industrial scale at the Donetsk Chemical Reagents Factory.

Similar content being viewed by others

Literature cited

P. I. Yashcheritsin, S. A. Popov, and N. S. Nasrman, Modern Methods for the Finish Machining of Parts [in Russian], Belarus', Minsk (1978).

E. G. Konovalov and G. S. Shchulev, The Finish Machining of Parts in a Magnetic Field with Ferromagnetic Powders [in Russian], Nauka Tekh., Minsk (1967).

F. I. Sakulevich, L. K. Minin, and L. A. Olender, Magnetoabrasive Machining of Precision Parts [in Russian], Vishéishaya Shkola, Minsk (1977).

Yu. M. Baron, “Physicochemical principles of operation of magnetoabrasive materials,” in: Magnetoabrasive Materials and Methods of Testing Thereof [in Russian], Kiev (1980), pp. 10–17.

G. G. Gnesin, M. D. Krymskii, and L. K. Tul'chinskii, “Principles of production of magnetoabrasive materials,” in: Magnetoabrasive Materials and Methods of Testing Thereof [in Russian], Kiev (1980), pp. 17–24.

G. D. Nalivka, V. S. Polishchuk, and A. N. Stepanchuk, “Some properties of magnetoabrasive powders from pseudofused Fe-TiC composites,” Poroshk. Metall., No. 8, 83–86 (1979).

G. D. Nalivka and P. S. Kislyi, “Composite carbide-based powders for magnetoabrasive machining,” in: Magnetoabrasive Materials and Methods of Testing Thereof [in Russian], Kiev (1980), pp. 34–42.

V. K. Grigorovich, Electronic Structure and Thermodynamics of Iron Alloys [in Russian], Nauka, Moscow (1970).

V. V. Grigor'eva and V. M. Klimenko, in: Chromium Carbide Alloys [in Ukrainian], Izd. Akad. Nauk. Ukr. SSR, Kiev (1961), pp. 9–13.

G. V. Samsonov, A. D. Panasyuk, G. D. Kozina, and L. V. D'yakonova, “Reactions of metal-like carbides with liquid transition metals,” in: Wettability and Surface Properties of Melts and Solids [in Russian], Naukova Dumka, Kiev (1972), pp. 95–98.

V. N. Eremenko, in: Multicomponent Titanium Alloys [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1962), pp. 67–74.

W. P. Fishel and V. Robertson, Am. Inst. Mining Eng., Mach., Paper No. 4, 1763 (1944); Chem. Abstr.,39, 1383 (1945).

S. B. Maslenkov, Applications of Electron Probe Microanalysis [in Russian], Metallurgiya, Moscow (1968).

L. N. Tul'chinskii and R. A. Davidenko, “Pickup for magnetization intensity measurements,” in: Theory, Methods, and Means of Measurement of Magnetic Quantities [in Russian], Leningrad (1977), pp. 106–110.

N. S. Khomin and G. D. Nalivka, “Operating performance of composite materials in magnetoabrasive polishing,” in: New Methods of Testing and Machining of Materials [in Russian], Nauka Tekh., Minsk (1975), pp. 189–195.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 3(243), pp. 94–100, March, 1983.

Rights and permissions

About this article

Cite this article

Polishchuk, V.S., Nalivka, G.D. & Kisel', N.G. Composite magnetoabrasive TiC-Fe, VC-Fe, and Cr-C-Fe powders. Powder Metall Met Ceram 22, 238–242 (1983). https://doi.org/10.1007/BF00793927

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00793927