Conclusions

-

1.

A study was made of the following methods of milling of ferrochromium: in a vibratory ball mill under alcohol and acetone and in a planetary mill. The most effective was milling for 30 min in the planetary mill, which comminuted 90% of ferrochromium to a particle size of less that 200Μ.

-

2.

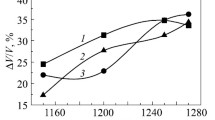

The optimum conditions for the production of TiC-Kh12M-steel materials (50, 40, 35, and 30% TiC) with chromium added to the steel in the form of ferrochromium powder were found to be a pressing pressure of 3 tons/cm2, a vacuum sintering temperature of 1430–1470‡C, and a sintering time of 1 h. The optimum conditions for the heat treatment (annealing, quenching, and tempering) of these materials were determined.

-

3.

Some of the key properties of the materials were investigated. It was established that the properties of TiC -Kh12M-steel materials alloyed with chromium in the form of ferrochromium are virtually identical with those of the same materials containing additions of pure chromium powder. Ferrochromium, however, being cheaper and more readily available than chromium powder, should be used as a starting material in the manufacture of titanium-carbide-steel alloys.

Similar content being viewed by others

Literature cited

J. Ellis, M. Gregory, and M. Epner, Progr. Powder Met.,16, 76 (1960).

S. S. Kiparisov, V. K. Narva, and L. I. Dalyaeva, New Wear-Resistant Materials Containing Titanium Carbide [in Russian], Izd-vo TsIIN “Tsvetmetinformatsiya” (1972).

S. S. Kiparisov and V. K. Narva, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Met., No. 3 (1969).

S. S. Kiparisov, I. V. Paisov, and V. K. Narva, Poroshk. Met., No. 9 (1969).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 2(170), pp. 49–52, February, 1977.

Rights and permissions

About this article

Cite this article

Kiparisov, S.S., Narva, V.K. & Seliverstova, O.V. Effect of method of addition of chromium to titanium-carbide-Steel alloys on their properties. Powder Metall Met Ceram 16, 118–121 (1977). https://doi.org/10.1007/BF00793788

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00793788