Conclusions

-

1.

Milling in a planetary mill raises the level of crystal lattice microdistortions in chromium oxide powder, reduces the particle size of the powder, and breaks up its mosaic blocks. The kinetics of the variation of the particle and block sizes is characterized by saturation.

-

2.

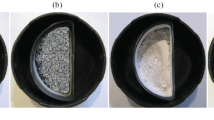

Fine crystal structure defects are annealed out in the temperature range 900–1100°C. Marked densification of chromium oxide during calcining in a reducing atmosphere begins at 1300°C.

-

3.

Milling as a means of activation substantially improves the sintering of Cr2O3 powders at temperatures of 1500–1600°C. For activated chromium oxide powders a correlation is found between the degree of sintering and the level of structural defectiveness.

Similar content being viewed by others

Literature cited

D. Lewis and M. W. Lindley, J. Am. Ceram. Soc.,47, No. 12, 652 (1964).

R. Schrader and G. Kneschke, “Mechanical activation of magnesia for sintering,” Proceedings of the 9th Conference on Industrial Silicates, Budapest (1968).

A. C. Greenham and B. P. Richards, Trans. Brit. Ceram. Soc.,69, No. 3, 115 (1970).

M. J. Klein and P. S. Rudman, Phil. Mag.,14, No. 132, 1199 (1966).

R. W. Heckel and J. L. Youngblood, J. Am. Ceram. Soc.,51, No. 7, 398 (1968).

Ya. E. Geguzin, The Physics of Sintering [in Russian], Fizmatgiz, Moscow (1967).

B. Warren, in: Advances in Metal Physics [Russian translation], Vol. 5, Metallurgizdat, Moscow (1963), p. 172.

O. R. Bergman and J. Barrington, J. Am. Ceram. Soc.,49, No. 9, 502 (1966).

O. V. Bogorodskii and Ya. S. Umanskii, Izv. Akad. Nauk SSSR, Ser. Fiz.,20, No. 6, 614 (1956).

A. I. Zharov, M. S. Mikhalev, et al., Fiz. Metal, i Metalloved.,31, No. 5, 1069 (1971).

P. P. Budnikov and S. G. Tresvyatskii, Dokl. Akad. Nauk SSSR,45, No. 5, 1041 (1954).

W. L. Smith, J. Appl. Cryst.,5, No. 2, 127 (1972).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 2(158), pp. 17–21, February, 1976.

Rights and permissions

About this article

Cite this article

Alapiti, B.G., Degtyareva, F.V., Karyakina, É.L. et al. Activation and sintering of chromium oxide powders. Powder Metall Met Ceram 15, 96–99 (1976). https://doi.org/10.1007/BF00793557

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00793557