Conclusions

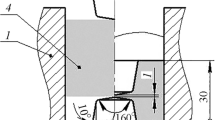

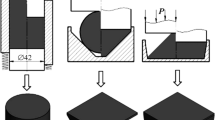

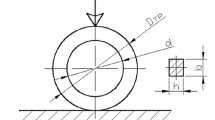

A study has been made of the character of the redistribution of volumes of a porous blank during hot forging with elements of extrusion; the feasibility is shown of controlling the process with the aim of ensuring that certain volumes of material occupy the required positions. It has been confirmed by experiment that the process of hot forging of porous materials with elements of extrusion involves more than one stage. The character of pressing pressure variation in various stages has been determined. In pressing in conical dies densification of central volumes of material lags slightly behind that of peripheral regions. For specimens of the geometric parameters investigated, the width of the peripheral blank zone, which in the steady-state extrusion stages moves parallel to the compressing part of the die, is (0.15–0.20)Dc. The degree of deformation and the redistribution of volumes of material in peripheral layers are affected mainly by the temperature conditions of the pressing process and to a much smaller extent by the starting blank porosity.

Similar content being viewed by others

Literature cited

V. Yu. Dorofeev and V. I. Lozovoi,“Some features of the densification of a P/M material during hot forging with elements of extrusion,” Poroshk. Metall., No. 3, 11–14 (1985).

G. L. Petrosyan, G. V. Musaelyan, and Kh. L. Petrosyan,“Extrusion of a sintered porous material through a conical die,” Poroshk. Metall., No. 3, 19–23 (1985).

Yu. G. Dorofeev, É. S. Baidala, and I. A. Kosobokov,“Determination of the pressing force-density relationship in the hot forging of porous powder preforms,” Poroshk Met all., No. 3, 20–23 (1984).

M. S. Koval'chenko, Theoretical Principles of Hot Plastic Working of Porous Materials [in Russian], Naukova Dumka, Kiev (1980).

Yu. G. Dorofeev, A. V. Kostenko, and I. A. Kosobokov, “Effect of starting porosity of P/M blanks on the energy and force parameters of dynamic hot pressing,” in: Transactions of the Fourth All-Union Scientific-Technical Conference on Hot Pressing in Powder Metallurgy [in Russian], Novocherkassk (1981), pp. 3–8.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 6(282), pp. 15–19, June, 1986.

Rights and permissions

About this article

Cite this article

Dorofeev, V.Y., Kosobokov, I.A. Deformation of porous materials during hot forging combined with extrusion. Powder Metall Met Ceram 25, 455–459 (1986). https://doi.org/10.1007/BF00792377

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00792377