Conclusions

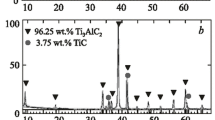

Titanium carbide ingots were produced by melting a charge consisting of titania and carbon black in an arc furnace. Powders produced by mechanical comminution of the ingots consisted of grains characterized by a low heterogeneity indicator and a mean strength indicator exceeding one and a half to two times that of the TiC-2 powders being manufactured by industry on a series scale.

Similar content being viewed by others

Literature cited

L. S. Golubyak, V. I. Mal'nev, A. N. Koshchuk, and V. I. Mel'nik, “Effect of melting conditions on the structure and some properties of titanium carbide,” Sverkhtverd. Mater., No. 6, 19–23 (1980).

G. V. Samsonov, A. A. Adamovskii, A. I. Bezykornov, et al., “Abrasive properties of fused titanium and zirconium carbides,” Sintetich. Almazy, No. 4, 28–31 (1973).

A. N. Stepanchuk and V. E. Shlyuko, “Device for melting refractory compounds,” Poroshk. Metall., No. 1, 108–112 (1969).

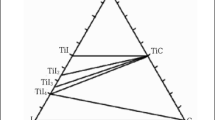

V. N. Eremenko, Titanium and Its Alloys [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1960).

J. R.Tinklepaugh and W. B.Crandall (eds.), Cermets, Reinhold Publ. Corp., New York; Chapman and Hall, London (1960).

A. A. Adamovskii, “Some properties of titanium carbide and Geksanit A abrasive powders,” Sintetich. Almazy, No. 3, 32–34 (1970).

G. V. Samsonov, A. A. Adamovskii, V. S. Polishchuk, and N. I. Gesherova, “Abrasive properties of pseudofused titanium carbide powder,” Poroshk. Metall., No. 11, 44–47 (1976).

V. S. Voblikov, Yu. P. Kornilov, and V. I. Nozdrachev, “Method of assessing the uniformity of composition of diamond powders by their grain strength,” in: Modern Synthetic Superhard Materials and Their Fields of Application [in Russian] (1975), pp. 25–28 (Tr. Vses. Nauchno-Issled. Inst. Almaza, No. 4).

E. I. Moshkovskii, T. I. Shaposhnikova, A. B. Lyashchenko, and L. V. Strashinskaya, “Morphology of the surface of titanium carbide powder particles,” Poroshk. Metall., No. 1, 93–98 (1985).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 6(282), pp. 1–4, June, 1986.

Rights and permissions

About this article

Cite this article

Lyashchenko, A.B., Khaenko, B.V., Ershova, L.S. et al. Titanium carbide produced by melting TiO2 + C. Powder Metall Met Ceram 25, 443–445 (1986). https://doi.org/10.1007/BF00792374

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00792374