Conclusions

-

1.

Experimental evidence clearly indicates that under conditions of identical total porosity in respective materials, the strength of compacts from atomized iron powder increases and the mechanical properties (σtr,σt, andδ) of the resultant material in the sintered condition improve with decreasing mean pore size of the material. Fine porosity achieved by pressing a mixture of specially chosen fractions is preferable to the fine porosity of a material obtained from a fine single fraction, because it ensures an optimum combination of powder compressibility and compact strength, as a result of which pressing and sintering under the same conditions enable higher density and strength and better ductility to be attained.

-

2.

From the results of an investigation of the processing properties exhibited by mixtures of reduced and atomized iron powders (with or without 0.8% zinc stearate), it follows that the poor compactibility characteristic of atomized iron powder can be substantially improved by adding to it a suitable amount of reduced iron powder, although this measure has an adverse effect on its apparent density and compressibility.

-

3.

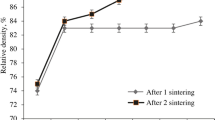

At a given porosity (12%) the mechanical properties of materials produced by pressing and sintering various types of iron powder (atomized, reduced, and their mixtures) are virtually identical (σt= 20–21 kgf/mm 2,δ = 13.8–14.6%), but after pressing and sintering under the same conditions better mechanical properties are obtained with atomized iron powder, which is characterized by higher compressibility.

Similar content being viewed by others

Literature cited

A. F. Zhornyak and V. E. Oliker, “Effect of particle-size distribution on the processing properties of atomized iron powder with and without a zinc stearate addition,” Poroshk. Metall., No. 4, 1–5 (1978).

Yu. N. Semenov, “New methods for controlling the quality of metal powder compacts,” in: Improvements in Methods of Shaping of Parts from Powders [in Russian], Izd. IPM Akad. Nauk Ukr. SSR, Kiev (1976), pp. 156–160.

M. Yu. Bal'shin, Powder Metal Science[in Russian], Metallurgizdat, Moscow (1948).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 7(187), pp. 86–90, July, 1978.

Rights and permissions

About this article

Cite this article

Zhornyak, A.F., Oliker, V.E. Effect of the particle-size distribution of atomized iron powder and mixtures of atomized and reduced iron powders on some properties of materials produced from them by pressing and sintering. Powder Metall Met Ceram 17, 558–561 (1978). https://doi.org/10.1007/BF00791936

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00791936