Conclusions

-

1.

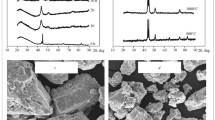

Specimens produced by the shock loading of powders have a two-phase structure consisting of particles of the matrix metal surrounded by a film of oxides of this metal.

-

2.

The presence of an almost continuous oxide film at the particle boundaries has no marked effect on the initial recrystallization temperature of specimens, but appreciably delays the process of collective recrystallization. Such oxides substantially lower the ductility of the resultant material, whose deformation leads to brittle rupture along the boundaries of individual particles.

-

3.

High-temperature heating and, particularly, hot plastic deformation give rise to a redistribution of particles of the second phase in nickel and iron specimens and their coagulation in the form of discrete inclusions. This increases ductility, making it possible to obtain, during the deformation of such specimens, up to 50% of cases of ductile rupture throughout the body of the grain.

-

4.

The character of the processes occurring during heating depends to a large extent on the stability] of the oxides introduced during explosive pressing and has a direct effect on the ductility of the resultant metal.

Similar content being viewed by others

Literature cited

I. I. Kornilov, Nickel and Its Alloys [in Russian], Izd-vo AN SSSR, Moscow (1958).

T. N. Rhodin, J. Am. Chem. Soc.,72, 5102 (1950).

A. B. Winterbottom, Trans. Electrochem. Soc.,76, 326 (1939).

Yu. A. Bagaryatskii (editor), X-Ray Radiography in Physical Metallurgy [in Russian], Metallurgizdat, Moscow (1961).

W. Bollman, in: New Electron-Microscopical Investigations [Russian translation], Metallurgizdat, Moscow (1961).

D. McLean, Mechanical Properties of Metals [Russian translation], Metallurgizdat, Moscow (1965).

O. A. Esin and P. V. Gel'd, Physical Chemistry of Pyrometallurgical Processes [in Russian], Vol. 1, Metallurgiya, Moscow (1966).

V. I. Arkharov, Oxidation of Metals [in Russian], Gos. Nauchno-Tekhn. Izd-vo Lit. po Chern. i Tsvet. Metallurgii, Sverdlovsk-Moscow (1945).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 9 (105), pp. 60–64, September, 1971.

Rights and permissions

About this article

Cite this article

Grishina, A.I., Mantaroshin, A.P. & Pashkov, P.O. Hardness loss and ductility of metal prepared by the method of impact loading of powders. Powder Metall Met Ceram 10, 728–731 (1971). https://doi.org/10.1007/BF00791850

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00791850