Conclusions

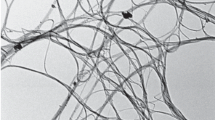

The introduction of 0.2- to 6-μm carbon particles into zirconium carbide leads to a nonmonotonic variation of the strength, fracture toughness, and thermal fatigue resistance of the resultant zirconium carbide-carbon composites as functions of free carbon content, with maxima at about 2.5 wt. %. Coarser (50-μm) carbon particles added in larger quantities have a deleterious effect on the strength properties. The addition of a carbon component to zirconium carbide can, depending on the nature of the former, both increase (synthetic diamond and PGI graphite) and decrease (KLZ graphite) the thermal fatigue resistance of the resultant composite.

Similar content being viewed by others

Literature cited

F. F. Lang, “Rupture of composites with disperse particles in a brittle matrix,” in: Composite Materials [Russian translation], Vol. 5, Moscow (1978), pp. 11–57.

N. Harada, S. A. Bortz, S. L. Blum, et al., “Production technology and properties of composite materials of the metal carbide-graphite system,” in: New Refractory Metallic Materials [Russian translation], Moscow (1971), pp. 265–288.

E. G. Kendall, R. D. Karnachan, and R. C. Rossi, “Hypereutectic carbides highly resistant to thermal shock,” J. AIAA,2, No. 1, 97–99 (1965).

E. G. Kendall, J. J. Slaughter, and W. C. Riley, “A new class of hypereutectic carbide composites,” J. AIAA,4, No. 5, 900–905 (1966).

P. V. Gerasimov, V. I. Groshev, and L. B. Nezhevenko, “A method of manufacture of parts from carbide-containing materials,” Inventor's Certificate No. 505521, Byull. Izobret., No. 9 (1976).

L. B. Nezhevenko, I. I. Spivak, P. V. Gerasimov, et al., “Sintering of zirconium and niobium carbides with carbon additions,” Poroshk. Metall., No. 8, 23–28 (1980).

V. S. Egorov and V. P. Popov, “Limiting thermal stresses in disks of brittle materials,” Probl. Prochn., No. 11, 53–56 (1975).

R. A. Andrievskii, A. G. Lanin, and G. A. Rymashevskii, Strength of Refractory Compounds [in Russian], Metallurgiya, Moscow (1974).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 1(229), pp. 67–74, January, 1982.

Rights and permissions

About this article

Cite this article

Gerasimov, P.V., Egorov, V.S., Lanin, A.G. et al. Strength of zirconium carbide composites with disperse carbon inclusions. Powder Metall Met Ceram 21, 59–64 (1982). https://doi.org/10.1007/BF00791729

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00791729