Conclusions

-

1.

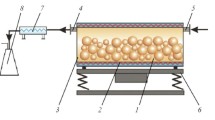

Tests were carried out on a vibratory mill enabling small amounts of materials (1–50 g) to be comminuted in a vacuum or in an inert atmosphere. The kinematics of the vibratory mill prevents its rod from bending and minimizes the wear of its journal bearings.

-

2.

In an investigation into the kinetics of comminution of telluride materials it was found that after a certain period of time comminution was accompanied by an oppositely directed process, namely agglomeration of fine particles.

Similar content being viewed by others

Literature cited

H. J. Rosier and W. Schrön, Z. Angew. Geol.,15, No, 7, 380–384 (1969).

L. V. Agafonov, S. I. Golosov, and N. G. Pyatiletova, in: Physicochemical Changes Occurring in Minerals during Ultrafine Comminution [in Russian], Nauka, Novosibirsk (1966), pp. 48–59.

N. S. Khodakov, in: Physicochemical Mechanics of Disperse Structures [in Russian], Nauka, Moscow (1966), pp. 141–153.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 9(177), pp. 105–107, September, 1977.

The authors wish to thank Professor V. A. Karzhavin for helpful discussion of the results of this work.

Rights and permissions

About this article

Cite this article

Stavrianidis, S.A., Markeliya, R.A. & Zarkua, O.A. Production of small quantities of finely divided unoxidized materials in a vibratory mill. Powder Metall Met Ceram 16, 737–739 (1977). https://doi.org/10.1007/BF00791478

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00791478