Conclusions

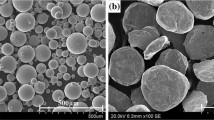

An investigation into the structure and morphology of a 30KhN3MF steel powder produced by atomizing a jet of liquid metal with nitrogen has shown that the rapid cooling experienced by the particles of such a powder ensures a predominantly cellular character of solidification. In the particles of the 30KhN3MF steel powder intercellular microsegregation of alloying and impurity elements is observed. A P/M material produced by HIP is free from internal discontinuities, but individual granules surrounded by oxide films are clearly visible in its macro- and microstructures. The presence of these films, by disturbing the homogeneity of material, has an adverse effect on the mechanical properties of the steel after HIP. P/M 30KhN3MF steel fractures over the surfaces of its powder particles. Plastic working and subsequent heat treatment of 30KhN3MF steel sheets ensures that, at the same level of toughness and strength and ductility characteristics in static tensile testing, the work of crack propagation is greater compared with 30KhN3MF steel produced by the orthodox process. The rupture of 30KhN3MF steel sheet has a dual character, tough, fine-grained fracture predominating between the oxide film layers, along which regions of lamination and cleavage can be detected.

Similar content being viewed by others

Literature cited

A. F. Belov, N. F. Anoshkin, V. I. Khodkin, O. Kh. Fatkullin, and M. Z. Ermanok, in: Processing of Light and Heat-Resisting Alloys [in Russian], Nauka, Moscow (1976), pp. 217–236.

A. I. Kolpashnikov and A. V. Efremov, Granulated Materials [in Russian], Metallurgiya, Moscow (1977).

E. D. Weisert and P. Schwarzkopf, “Isostatic pressing: a three-dimensional process” Met. Progr., 71–74, Apr., 1974.

C. Moore, “Use of argon and nitrogen in the powder metallurgy of high-duty alloys,” Metall. Met. Forming,41, No. 6, 179–182, June, 1974.

I. Ya. Kondratov, N. G. Minaev, et al., “Production and properties of sintered high-speed steel,” Poroshk. Metall., No. 5, 96–100 (1974).

M. Flemings, Solidification Processing, McGraw-Hill (1974).

Author information

Authors and Affiliations

Additional information

A low-alloy 0.30% C-Cr-3% Ni-Mo-V grade-Translator.

Translated from Poroshkovaya Metallurgiya, No. 9(213), pp. 77–82, September, 1980.

Rights and permissions

About this article

Cite this article

Ezhov, A.A., Shvarts, V.I., Bernshtein, L.M. et al. Hereditary influence of the starting structure of powder particles on the mechanical properties of 30KhN3MF constructional steel. Powder Metall Met Ceram 19, 643–646 (1980). https://doi.org/10.1007/BF00790558

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00790558