Conclusions

-

1.

Disappearance of excess point defects in heat-resistant nickel alloy KhN65VMTYu begins with heating to 100° and ends at ∼250°.

-

2.

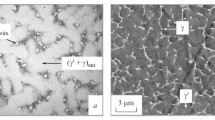

A substantial change in the polygonal structure is observed with heating to 750–850°. Improvement of the intragranular structure continues in the process of secondary recrystallization — up to 1160–1180°.

-

3.

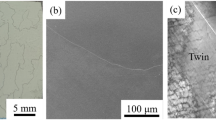

Primary recrystallization begins at 900–950° and ends at 980–1020°, depending on the extent of preliminary cold working.

-

4.

The temperature dependence of secondary recrystallization depends to a considerable extent on the temperature at which dispersed phases go into solution. The rate of secondary recrystallization obeys a parabolic rule. Increasing the temperature and the extent of hot deformation slightly increases the susceptibility to secondary recrystallization. The optimal recrystallization annealing treatment for the OA heat is 1180° for 2–3 h, and 1160° for 2–3 h for the OI heat.

-

5.

Differences in grain size in microvolumes with ε > εcr are affected mainly by uneven distribution of dispersed phases.

-

6.

Lowering the forging temperature leads to quite uneven deformation through the bulk of the forging and substantial differences in grain size in macrovolumes; the optimal final forging temperature is 1160°.

Similar content being viewed by others

Literature cited

F. F. Khimushin, Heat-Resistant Steels and Alloys [in Russian], Metallurgiya, Moscow (1964), p. 124.

L. B. Getsov, Materials and Strength of Gas Turbine Parts [in Russian], Mashinostroenie, Moscow (1973).

S. S. Gorelik, Recrystallization of Metals and Alloys [in Russian], Metallurgiya, Moscow (1967), p. 43.

P. Feltham and S. Newcomb, "Internal friction in copper and α brass in the process of plastic deformation," in: Internal Friction in Metallic Materials [Russian translation], Nauka, Moscow (1970), p. 68.

E. I. Mozzhukhin and A. A. Belyakov, "Recovery of internal friction during annealing of highly deformed molybdenum," in: Internal Friction in Metallic Materials [in Russian], Nauka, Moscow (1970), p. 79.

E. Macherauch, Z. Metallk.59, No. 8, 669 (1968).

S. Z. Bokshtein, S. S. Ginzburg, and E. A. Torosyan, "Effect of grain boundary inheritance and properties of recrystallized nickel alloys," Metalloved. Term. Obrab. Met., No. 8, 61 (1976).

E. S. Zasimchuk, Polygonization, Recrystallization, and Thermal Stability of the Properties of Materials [in Russian], Naukova Dumka, Kiev (1976), p. 44.

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 33–37, May, 1979.

Rights and permissions

About this article

Cite this article

Levin, E.E., Tikhonov, V.I. Effect of various factors on the recovery and recrystallization of a nickel-base heat-resistant alloy. Met Sci Heat Treat 21, 367–371 (1979). https://doi.org/10.1007/BF00780776

Issue Date:

DOI: https://doi.org/10.1007/BF00780776