Conclusions

-

1.

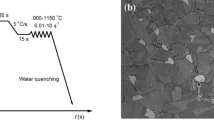

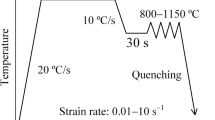

In steel 4Kh4VMFSSh with an original grain size of grade 2–3 a homogeneous austenitic structure (grade 5.5–6) is formed under conditions of dynamic recrystallization after 15–50% deformation at 1100–1150°C. In steel 45Kh3V3MFSSh with an original grain size of grade 4–5 a homogeneous recrystallized structure with grain size of grade 7.5–8.5 is formed after 18–50% deformation at 1150–1200°C and also after 50% deformation at 1100°C. At other temperatures and deformations the austenite grain size either remains unchanged or it is refined, but not through the entire volume.

-

2.

Phase recrystallization of steels 4Kh4VMFSSh and 45Kh3V3MFSSh cooled from deformation temperature in air is not accompanied by austenite grain refining if no recrystallization induced by mechanical cold working develops.

-

3.

Austenitizing of deformed steels induces no essential changes in the structure even at the optimal temperature −1050°C for steel 4Kh4VMFSSh and 1100°C for steel 45Kh3V3MFSSh. If a completely homogeneous structure is not formed during deformation, it cannot be obtained during austenitizing.

Similar content being viewed by others

Additional information

N. É. Bauman Moscow Technical College. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 55–58, June, 1979.

Rights and permissions

About this article

Cite this article

Kryuchkov, V.I., Kucheryavyi, V.I. & Ul'yanova, N.V. Effect of hot deformation and austenitizing on the grain size of steels 4Kh4VMFSSh and 45Kh3V3MFSSh. Met Sci Heat Treat 21, 477–480 (1979). https://doi.org/10.1007/BF00780490

Issue Date:

DOI: https://doi.org/10.1007/BF00780490