Conclusions

-

1.

As the result of carbonitriding the hardness of high speed samples increases an average of HV 200–300.

-

2.

The optimum carbonitrided case thickness, 0.02–0.03 mm, is reached in 10–15 min for R6M5, R18F, R12F2K8M3, and R12F3 steels and in 20–25 min for R6M5K5 and R9M4K8 steels.

-

3.

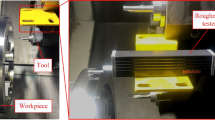

After carbonitriding cutting tool life increases by three to four times.

-

4.

The carbonitriding process does not require complex equipment and makes it possible to obtain a high rate of heating and to decrease thermal stresses and warping of the tool.

Similar content being viewed by others

Literature cited

Yu. M. Lakhtin and Ya. D. Kogan, Nitriding of Steel [in Russian], Mashinostroenie, Moscow (1967).

A Feature of Heat Treatment of R6M5, R6M5K5, and R9M4K8 High Speed Steel Tools. Express Information [in Russian], No. 4, Series 1008, Tsent. Nauch.-Issled. Inst. Inf. Tekh.-Ekonom. Issled. Min. Zagot. SSSR (1977).

Additional information

Kamaz Truck Plant. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 23–25, June, 1982.

Rights and permissions

About this article

Cite this article

Gesser, L.E., Sagitova, S.R. & Liberman, L.S. Influence of carbonitriding on the life of cutting tools. Met Sci Heat Treat 24, 399–402 (1982). https://doi.org/10.1007/BF00780443

Issue Date:

DOI: https://doi.org/10.1007/BF00780443