Conclusions

-

1.

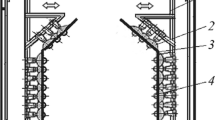

A heater has been developed on the basis of infrared radiation lamps for heating moving wire of refractory metals in vacuum.

-

2.

The IR heater is characterized by complete lack of gas liberation in vacuum and also low inertia. This ensures a high heating rate and high speed of the wire (0.4–0.5 m/sec).

-

3.

The IR heater is small, simple, reliable in operation, and is easily installed in any equipment as well as in production lines.

-

4.

The efficiency of the IR heater increases in vacuum due to the higher temperature (300–400° higher) for the same power.

Similar content being viewed by others

Literature cited

S. N. Broneev et al., Pressing of Refractory Metals and Alloys [in Russian], Metallurgiya, Moscow (1975).

S. N. Brodskii et al., Equipment for Heat Treatment of Refractory Metals in Electrovacuum Production [in Russian], Énergiya, Moscow (1969).

S. P. Kundas, “Apparatus for flattening microbands of hard-to-work metals based on UVN-2M-1,” in: Development of KSUK at Radio-Electronic Enterprises and the Increase in Production of High-Quality apparatus [in Russian], Part II, Minsk (1978), p. 81.

Additional information

Minsk Radio Engineering Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 18–19, April, 1980.

Rights and permissions

About this article

Cite this article

Tyavlovskii, M.D., Tkhostov, M.K.M. & Kundas, S.P. Heating of wire of refractory metals by means of infrared radiation. Met Sci Heat Treat 22, 250–252 (1980). https://doi.org/10.1007/BF00779873

Issue Date:

DOI: https://doi.org/10.1007/BF00779873