Conclusions

-

1.

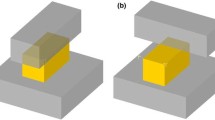

Treatment of the liquid phase of ingots with a pulsating submerged jet in the process of solidification reduces the depth of penetration of shrinkage defects; this makes it possible to reduce the weight of the riser by 15–20%.

-

2.

In an ingot subjected to pulsation the zone of columnar crystals becomes shorter, the zone of equiaxial crytals becomes more homogeneous, and eccentric liquation is also shifted from the zone solidifying directly under pulsation; this may be regarded as one way of controlling the formation of the macrostructure of forging ingots.

-

3.

In the metal of the head part of the experimental ingot the steel is less polluted by nonmetallic inclusions than in the control ingot. The greatest difference is a characteristic feature of the zone solidifying directly in the process of pulsation.

Similar content being viewed by others

Literature cited

The Influence of External Effects on Liquid and Crystallizing Metal [in Russian], IPL Akad. Nauk Ukr. SSR, Kiev (1983).

M. S. Flemings, "Solidification processing," Metall. Trans.,5, October, 2121–2134 (1974).

V. L. Pilyushenko, A. N. Smirnov, and Yu. V. Pettik, "The effectiveness of vibromechanical action on liquid and solidifying metal," Chermetinform., Chern. Metall., No. 1, 18–29 (1990).

Continuous Castings: The Application of Electromagnetic Stirring (EMS) in the Continuous Casting of Steel, Vol. 3, Michigan (1984).

S. P. Efimenko, V. L. Pilyushenko, and A. N. Smirnov, Pulsation Stirring of Metallurgical Melts [in Russian], Metallurgiya, Moscow (1989).

V. L. Pilyushenko, A. N. Smirnov, A. S. Plakhotnyi, et al., "Improvement of the quality of ingots by subjecting the solidifying melt to the effect of a submerged pulsating jet," Stal', No. 11, 37–40 (1989).

A. S. Plakhotnyi, S. V. Pil'guk, N. V. Borzykh, et al., "Improving the quality of forging ingots by the method of pulsating stirring," Énergomashinostroenie, No. 9, 35–37 (1988).

Y. Ito, N. Masumitsy, and K. Matsubara, "Formation of manganese sulfide in steel," Transactions ISU,21, 477–484 (1981).

Ya. N. Malinochka and G. Z. Koval'chuk, Sulfides in Steels and Cast Iron [in Russian], Metallurgiya, Moscow (1988).

V. S. Kovalenko, E. L. Zats, and V. P. Cherkasova, "Metallographic method of evaluating the pollution of deformed steel," Zavod. Lab.,38, No. 8, 958–961 (1972).

Additional information

Donetsk Polytechnic Institute; VNIIPVtortsvetmet. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 21–22, July, 1991.

Rights and permissions

About this article

Cite this article

Smirnov, A.N., Bychkov, Y.B., Chernobaeva, T.V. et al. Quality of forging ingots of low alloy steel pulsation treated in solidification. Met Sci Heat Treat 33, 508–512 (1991). https://doi.org/10.1007/BF00778650

Issue Date:

DOI: https://doi.org/10.1007/BF00778650