Conclusions

-

1.

Use of the relative length of a stable crackl c/b, where b is specimen width, is proposed for evaluation of the fracture resistance of a steel and determination of the critical defect size.

-

2.

09G2S steel has higher impact strength and crack resistance and a lower ductile-to-brittle transition temperature but a greater anisotropy of properties than 20 steel.

-

3.

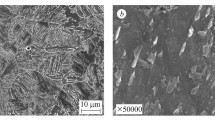

In fractures of specimens of 20 and 09G2S steels at temperatures of the ductile-to-brittle transition in impact bend and static tensile tests zones of drawing out (Θ 1) and of shear (Θ 2) and separation (Θ 3) fracture were observed. Their total is the zone of stable crack growth (l c). The ductile-to-brittle transition temperature of 20 steel determined from the fibrous constituent in the fracture (F=50%) is practically independent of notch sharpness of the specimens used.

Similar content being viewed by others

Literature cited

SNIP 2.05.06.85. Main-Line Piping. Gos. Sovet Stroit. SSSR [in Russian], Tsent. Nauch.-Issled. Inst. Tip. Proekt. Gos. Sovet Stroit. SSSR, Moscow (1985).

Calculations and Tests for Strength in Machine Building. A Fractographic Method of Determination of the Ductile-to-Brittle Transition Temperature of Metallic Materials, Preprint MR 5-81-M [in Russian], Vsesoyuz. Nauch.-Issled. Inst. Norm. Mashinostr., Gos. Kom. SSSR Stand. (1981).

A. P. Gulyaev, “Ductile and brittle fracture”, Metalloved. Term. Obrab. Met., No. 7, 63–64 (1977).

M. N. Georgiev, The Ductility of Low-Carbon Steels [in Russian], Metallurgiya, Moscow (1973).

J. F. Knott, Fundamentals of Fracture Mechanics [Russian translation], V. G. Kudryashov (ed.), Metallurgiya, Moscow (19870.

J. Otani, Tetsudo Gidzuku Kanku Syre,14, No. 11, 503 (1957).

L. R. Botvina, The Kinetics of Fracture of Constructional Materials [in Russian], Nauka, Moscow (1989).

L. R. Botvina, E. I. Kolokolov, and P. F. Koshelev, “Determination of the ductile-to-brittle transition temperature in various forms of testing”, Metalloved. Term. Obrab. met., No. 7, 24–28 (1975).

A. P. Gulyaev, V. D. Zelenova, and I. V. Shermazan, “Determination of the ductile-to-brittle transition temperature by a microfractographic method”, Zavod. Lab.,32, No. 7, 870–872 (1966).

V. Z. Parton and E. M. Morozov, The Mechanics of Elastoplastic Fracture [in Russian], Nauka, Moscow (1974).

GOST 25.506-85. Methods of Mechanical Tests of Materials. Determination of the Characteristics of Crack Resistance (Fracture Toughness) in Static Loading [in Russian], Gos. Kom. SSSR Stand., Moscow (1985), pp. 35–37.

Additional information

A. A. Baikov Institute of Metallurgy. All-Union Petroleum and Gas Scientific-Research Institute, Samara. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 9–14, October, 1992.

Rights and permissions

About this article

Cite this article

Botvina, L.R., Tetyueva, T.V., Geikhman, T.D. et al. Features of the fracture of specimens of low-carbon steels under impact and static loading conditions. Met Sci Heat Treat 34, 614–621 (1992). https://doi.org/10.1007/BF00776899

Issue Date:

DOI: https://doi.org/10.1007/BF00776899