Conclusions

-

1.

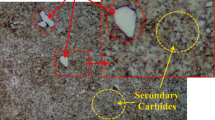

For punching and coining die parts the optimum combination of properties (high hardness of the base and wear resistance of the surface and sufficient core toughness) is obtained with a combination of chemicothermal and heat treatments (with water quenching of the container) only for Kh12M and KhVG steels (and primarily with use of carbide coatings).

-

2.

The following processes are recommended: for Kh12M steel chemicothermal treatment in a container with a fusible seal at 1050°C for 5 h, water quenching of the container with the parts; for KhVG steel chemicothermal treatment in a container with a fusible seal at 1000°C for 5 h, furnace cooling of the container, austenitizing in the same sealed container at 850°C for 2 h, water quenching of the container with the parts.

-

3.

For punching and coining dies (taking into consideration the proposed chemicothermal and heat treatment process) use of high-chromium type Kh12M steel is most desirable.

Similar content being viewed by others

Literature cited

A. P. Gulyaev, K. A. Malinina, and S. M. Saverina, Tool Steels. A Handbook, 2nd Edition Revised and Supplemented [in Russian], Mashinostroenie, Moscow (1975).

L. A. Poznyak, S. I. Tishaev, Yu. M. Skrynchenko, et al., Tool Steels. A Handbook [in Russian], Metallurgiya, Moscow (1977).

Additional information

Moscow Aviation Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 7–8, October, 1992.

Rights and permissions

About this article

Cite this article

Karpman, M.G., Sokolova, N.K., Dmitrieva, E.M. et al. Wear-resistant diffusion coatings on steels for punching and coining dies. Met Sci Heat Treat 34, 611–613 (1992). https://doi.org/10.1007/BF00776898

Issue Date:

DOI: https://doi.org/10.1007/BF00776898