Summary

-

1.

A study of slip casting as a method of formation of parts from MoSi2 has demonstrated the feasibility of production of shaped components by this process.

-

2.

Distilled water was found to be the best dispersion medium.

-

3.

It is shown that, when it is required to slip cast a coarse powder which settles in water, the viscosity of the slip may be increased by using bentonite or sodium alginate additions. In such a case, the thixotropic slip structure must be eliminated by an appropriate method.

-

4.

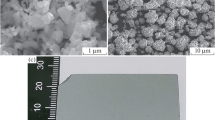

For slip casting using aqueous suspensions, molybdenum disilicide powder should be ground to 75% of fractions with particles less than 2 μ in diameter.

-

5.

Aqueous molybdenum disilicide slips exhibit two casting ranges, with pH values of 4–5 and 9–11. Slip casting using suspensions with pH values in the 9–11 casting range secures castings of higher quality, which resist cracking during casting and attain the maximum density.

-

6.

The density of parts produced by slip casting lies in the range of values attained by other methods of formation. Uniform particle packing throughout the whole section of a casting is an advantage of slip casting.

-

7.

During sintering, parts produced by the above-described slip casting procedure exihibit a high but uniform shrinkage and attain an adequate level of density with a porosity of about 8%.

Similar content being viewed by others

Literature cited

P. S. Kislyi and G. V. Samsonov, Izv. Akad. Nauk SSSR, Otdel. Tekhn. Nauk. Met. i Toplivo, No. 6, 133 (1959).

P. S. Kislyi, A. D. Panasyuk, G. V. Samsonov, A. G. Strel'chenko, Kh. Khavrunyak, and Serikov, Ogneupory, No. 2, 72 (1960).

R. Kieffer and F. Benesovsky, Planseeberichte für Pulvermetallurgie,5, 56 (1957).

Kiyosbi Tamura and Funtai Oyobi, Funmatsuyakin,10, No. 2, 44–50 (1963).

A. G. Dobrovol'skii and É. Ya. Popichenko, Poroshkovaya Met., No. 9 (1965).

G. P. Kalliga, Casting of Zirconium Parts [in Russian], Metallurgiya Press, Moscow (1964).

V. S. Kocho, G. V. Samsonov, and A. G. Strel'chenko, Continuous Monitoring of Steel Temperature during the Finishing Period [in Russian], Tekhnika Press, Kiev (1965).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dobrovol'skii, A.G., Nazarchuk, N.V. Slip casting of molybdenum disilicide. Powder Metall Met Ceram 5, 349–354 (1966). https://doi.org/10.1007/BF00775987

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00775987