Summary

-

1.

The investigation described has demonstrated the feasibility of preparation of sintered bronzes containing aluminum, manganese, iron, and silicon as alloying elements, using powder metallurgy methods with the introduction of the alloying additions in the form of powders of pure elements or addition alloys.

-

2.

Double compacting at pressures of 10–12 · 109 N/m2 yields material with a final porosity of 4–6%.

-

3.

The optimum sintering temperatures for bronzes of the compositions investigated range between 1173 and 1223°K.

-

4.

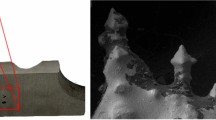

By employing the procedure described for the preparation of sintered bronzes, it is possible to obtain relatively stable and homogeneous structures, the phase composition of which is determined by the phase diagrams of systems of the elements contained in these sintered bronzes.

Similar content being viewed by others

Literature cited

M. Hansen and K. Anderko, Structure of Binary Alloys [Russian translation], I and II (Moscow, Metallurgizdat, 1962).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Miroshnikov, V.N., Fedorchenko, I.M. Investigation of the technology of bronze production by the powder metallurgy method. Powder Metall Met Ceram 5, 109–113 (1966). https://doi.org/10.1007/BF00775556

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00775556