Summary

-

1.

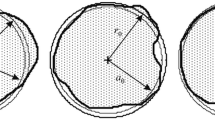

The densification behavior of Fe-ZrC, Fe-NbC, Fe-Mo2C, Ni-ZrC, Ni-NbC,Ni-Mo2C,Co-ZrC, Co-NbC, and Co-Mo2C mixtures was investigated. It was observed that increasing the carbide content of mixtures intended for pressing raises their porosity at pressures above 10–15 kg/m2 and lowers it at lower compaction pressures.

-

2.

The dependence of the density of compacts on compaction pressure and carbide content was established. It was found that the magnitude n, which appears in Eq. (1), is a linear function of the amount of the second component over a wide range of carbide contents of a mixture. The magnitudes n0 and K0 in Eq. (4) are determined by the physicomechanical properties of the mixture components.

-

3.

It was demonstrated that the presence of a lubricant (solution of synthetic rubber in benzine) exerts no significant influence on the value of n and on its rate of variation, i.e., on the value of K0.

-

4.

The effects of compaction pressure and the amount of a second component on compact porosity was studied. A hypothesis is advanced postulating that the same mechanism controls the deformation of sintered metal-powder materials and the deformation of powders subjected to densification in a closed die in the second stage of compaction.

Similar content being viewed by others

Literature cited

I. D. Radomysel'skii and N. I. Shcherban', Poroshkovaya Met., No. 4, 45 (1966).

A. G. Yurchenko, L. I. Pugina, and N. I. Shcherban', Poroshkovaya Met., No. 5, 19 (1969).

M. Yu. Bal'shin, Powder Metals Science [in Russian], Metallurgizdat, Moscow (1948).

G. V. Samsonov (editor), Physicochemical Properties of the Elements, Handbook [in Russian], Izd-vo “Naukova Dumka,” Kiev (1965).

G. V. Samsonov, Refractory Compounds [in Russian], Metallurgizdat, Moscow (1963).

P. E. Shaw and E. W. Leavey, Phil. Mag.,10, 809 (1930).

R. Holm and B. Kirschstein, Wiss. Veroeffentl.,15, No. 1 (1936).

F. P. Bowden and I. E. Young, Proc. Roy, Soc.,208, No. 1094 (1951).

E. Ryshkewitsch, J. Amer. Ceram. Soc.,36, 65 (1953).

A. F. Beloivan, G. V. Isakhanov, I. D. Radomysel'skii and N. I. Shcherban', Poroshkovaya Met., No. 5, 41 (1966); No. 4, 20 (1967); No. 6, 74 (1967); No. 12, 70 (1967).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 7 (79), pp. 7–12, July, 1969.

Rights and permissions

About this article

Cite this article

Petrova, E.M., Shcherban', N.I. & Sleptsov, V.M. Densification behavior of Fe, Co, and Ni powders with additions of zirconium, niobium, and molybdenum carbide powders. Powder Metall Met Ceram 8, 523–527 (1969). https://doi.org/10.1007/BF00775511

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00775511