Conclusions

-

1.

The phenomenon of slow cracking in quenched steels is a process of subcritical development of microscopic cracks (20–50 μm), which are generated during the loading of the samples in the macroelastic region. Upon increasing the loading rate, an effect of the deformation-rate retardation of crack nucleation (DRR effect) is observed which leads to the appearance of an incubation period of the crack nucleation at the tip of the stress concentrator. This point needs to be taken into account while performing the tests.

-

2.

The slow cracking of quenched steels is a particular case of hydrogen embrittlement of materials and is caused by the internal, diffusionally mobile hydrogen, which is formed during the quenching of the steel. Desorption of hydrogen during the course of the postquenching rest eliminates the tendency of steels toward slow fracture. In the example of a model steel, it is shown that the brittle state of the material including grain boundaries is an insufficient condition for the onset of slow cracking and that hydrogen needs to be present.

-

3.

Rest of quenched steels, which causes changes in the mechanical properties, exerts the greatest influence on the value of the crack-nucleation stress. The maximum effect of rest is found to be in the case of the 30KhGSA steel containing ∼0.3% C with a hardness of 50 HRC at a stress-concentrator radius of 0.1–0.2 mm. The kinetics of increase in the mechanical properties σn AE, σF of the quenched samples during the course of the rest is in agreement with the kinetics of desorption of the diffusionally mobile hydrogen to the atmosphere.

-

4.

The cause for the cases of slow cracking of objects and semifinished products observed in practice is the formation and growth of defects (cracks) of a quenching or casting origin on top of a high hydrogen content in the structure of the steel.

Similar content being viewed by others

References

Ya. M. Potak, High-Strength Steels [in Russian], Metallurgiya, Moscow (1972).

M. A. Balter, A. P. Lyubchenko, S. I. Aksenova, et al., Fractography — A Means of Diagnosties of Fractured Objects [in Russian], Mashinostroenie, Moscow (1987).

I. S. Toidorova, V. V. Zabil'skii, and V. I. Sarrak, "Slow fracture of martensitic steels — a review", Fiz. Met. Metalloved., No. 7, 5–11 (1991).

V. V. Velichko and V. V. Zabil'skii, "Slow cracking of quenched steels. A history of the problem, effect of various factors, and modern concepts — a review," Paper No. 1526-V91, Deposited with VINITI January 4, 1991.

V. I. Sarrak, T. K. Sergeeva, and G. A. Filippov, "Systematics of the time dependence of the strength of quenched steels", Metalloved. Term. Obrab. Met., No. 8, 25–30 (1976).

Ya. M. Potak, "A method of estimating the tendency of quenched steels to spontaneous cracking under the action of static loading", Zavod. Lab.,13, No. 1, 77–84 (1947).

S. S. Shurakov, "Delayed fracture in quenched steels and the effect of rest on their strength," Doctoral Dissertation, Leningrad (1961).

M. A. Smirnov, S. N. Petrova, and L. V. Smirnov, High-Temperature Thermomechanical Treatment and the Brittleness of Steels and Alloys [in Russian], Nauka, Moscow (1991).

V. R. Knyazeva, V. I. Sarrak, and G. A. Filippov, "Segregation of impurities and decohesion along grain bound-aries", Poverkh. Fiz. Khim. Mekh., No. 5, 64–68 (1982).

G. A. Filippov, V. N. Marchenko, D. A. Litvinenko, et al., "Effect of impurities on intercrystalline brittleness of the 18Kh2N4VA steel after quenching and tempering", Probl. Prochn., No. 2, 114–119 (1980).

G. A. Filippov, "Systematics of the slow-cracking phenomenon in high-strength steels and a method of increasing the resistance to cracking in steel objects," Doctoral Dissertation, Moscow (1989).

D. I. Maleev, G. M. Mikheev, T. N. Mogileva, "A laser in modulated and active-synchronization modes obtained by low-voltage modulators for VKR-spectroscopy of molecular hydrogen," Paper No. 1507, Deposited with VINITI, March 6, 1989.

G. M. Mikheev, V. V. Velichko, V. V. Zabil'skii, and D. I. Maleev, "Recording the kinetics of desorption of hydrogen from freshly quenched 30KhGSA steel by laser spectroscopy," in: Abstr. Repts. at the All-Union Conf. ‘Analiz-90’ [in Russian], Izhevsk (1990), Part 2, p. 309.

O. A. Bartenev, V. V. Zabil'skii, and V. V. Velichko, "Recording the kinetics of nucleation and growth of intercrystalline cracks by the acoustic-emission method", Zavod. Lab.,52, No. 10, 63–65 (1986).

V. V. Zabil'skii, O. A. Bartenev, and V. V. Velichko, "Investigation of slow cracking in a medium-carbon steel by the acoustic-emission method", in: Intercrystalline Brittleness of Steels and Alloys — A Collection of Scientific Papers [in Russian], Ural Sci. Ctr., Acad. Sci. USSR, Sverdlovsk (1987), pp. 109–120.

V. V. Zabil'skii, O. A. Bartenev, V. V. Velichko, and S. M. Polonskaya, "Fractographic and acoustic-emission observations of the nucleation of intercrystalline cracks during slow cracking [in Russian], Fiz. Met. Metalloved.,62, No. 4, 793–800 (1986).

V. V. Zabil'ski, V. V. Velichko, and S. M. Polonskaya, "Effect of microcracking and rate of loading of the nucleation of cracks during slow cracking", in: Structural phase transformations in Metals: Problems of Strength and Plasticity [in Russian], Ural Sci. Ctr., Acad. Sci. USSR, Sverdlovsk (1987), pp. 56–64.

O. S. Mnushkin and O. I. Kol'chenko, "Effect of hydrogen on the slow cracking of steel", Fiz.-Khim. Mekh. Mater., No. 1, 24–25 (1981).

V. V. Velichko, G. M. Mikheev, V. V. Zabil'ski, and D. I. Maleev, "Effect of ultralow concentrations of hydrogen on the mechanical properties of the quenched 30KhGSA steel", Fiz.-Khim. Mekh. Mater.,27, No. 1, 112–114 (1991).

V. V. Velichko, "An acoustic-emission investigation of slow cracking in a quenched steel,", Doctoral Dissertation, Izhevsk (1992).

V. V. Zabil'ski, V. V. Velichko, and A. Yu. Kazanskaya, "Slow cracking of steels and the two-phase ferrite-austenite structure", Fiz. Met. Metalloved., No. 3, 143–149 (1990).

V. V. Zabil'ski and V. V. Velichko, "Role of metallurgical hydrogen during the slow cracking of a cast steel with the delta-ferrite structure", Fiz.-Khim. Mekh. Mater.,25, No. 3, 17–21 (1989).

V. V. Zabil'skii, "The problem of temper embrittlement of structural alloy steels — a review", Metalloved. Term. Obrab. Met., No. 1, 24–31 (1987).

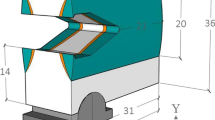

"A method for the mechanical test of high-strength brittle steels," USSR Patent No. 1402831, MKI G01 N3/00.

V. V. Zabil'ki and V. I. Lebedev, "Formation of transverse and network-type cracks and high-temperature embrittlement of steels during continuous casting", in: Ferrous Metallurgy [in Russian], Chermetinformatsiya, Moscow, Issue 2, No. 1102, 13–19 (1991).

Additional information

Fizikotechnical Institute, Ural Branch, Russian Academy of Sciences. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 9–15, April, 1993.

Rights and permissions

About this article

Cite this article

Zabil'skii, V.V., Velichko, V.V. Nature of the slow-fracture phenomenon in quenched steels. Met Sci Heat Treat 35, 198–206 (1993). https://doi.org/10.1007/BF00775137

Issue Date:

DOI: https://doi.org/10.1007/BF00775137