Conclusions

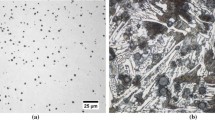

White cast iron powder rapidly quenched from the liquid condition with presence of the same phases and structural components differs markedly in structure from normally cast white iron.

-

2.

With an increase in cooling rate vcool during solidification the amount of eutectic decreases. However, with an increase in carbon content this tendency is weakened and with 3.9% the structure of powder cast iron is almost entirely of eutectic.

-

3.

An increase in vcool leads to a marked reduction in the dimensions of eutectic colonies and the eutectic component itself and also to refinement of primary carbide precipitates in hypereutectic cast irons.

-

4.

Austenite formed as a result of rapid solidification from the liquid condition is supersaturated with carbon.

Similar content being viewed by others

Literature cited

A. K. Petrov, I. S. Miroshnichenko, V. V. Parabin, et al., "Study of the solidification of metal powders obtained by atomizing a liquid phase," Poroshk. Metall., No. 1, 16–20 (1973).

D. Dyson and B. Holmes, J. Iron and Steel Inst.,208, 469 (1971).

V. Tofaute, C. Küttner, and A. Büttinghaus, "Das System Eisen-Chrom-Chrom-Karbid Cr7C3-Zementit," Arkhiv für das Eisenhüttenwesen,C12, Juni (1936).

Additional information

I. P. Bardin Institute of Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 34–35, January, 1991.

Rights and permissions

About this article

Cite this article

Gulyaev, A.P., Astakhov, S.I. Structural features of atomized white cast iron powder. Met Sci Heat Treat 33, 56–60 (1991). https://doi.org/10.1007/BF00775038

Issue Date:

DOI: https://doi.org/10.1007/BF00775038