Conclusions

-

1.

The structure and properties of bearing steels subjected to EBT depend to a considerable extent on their initial structure and on the composition of the carbide phase. Electron-beam hardening is expedient for treating steels with initial finely disperse structure. Maximal hardness and dislocation density is found in the zone of solid hardening with incomplete dissolution of carbides.

-

2.

In distinction to laser treatment, electron-beam treatment prevents decarburization of the surface layer and makes it possible to obtain a more uniform structure in the direction in which the beam moves, and a thicker hardened layer.

-

3.

To obtain high contact fatigue strength of bearing steels, electron-beam treatment has to be carried out without fusion of the surface under such conditions that the carbides are not completely dissolved and a strengthened layer forms.

-

4.

The contact fatigue strength of the rolling surfaces after electron-beam treatment depends on the thickness of the zone of secondary hardening. The life of surfaces after EBT treatment can be extended only if the strengthened layer is at least one-half thicker than the depth at which the zone of maximal tangential stresses arising in rolling lies.

Similar content being viewed by others

Literature cited

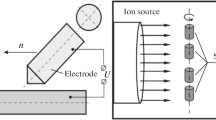

N. N. Rykalin, A. A. Uglov, I. V. Zuev, and A. N. Kokora, Laser and Electron-Beam Treatment of Materials (Handbook) [in Russian], Mashinostroenie, Moscow (1985).

I. L. Pobol', "Electron-beam heat treatment of metallic materials," Itogi Nauki i Tekhniki VINITI. Seriya Metallovedenie i Termicheskaya Obrabotka,24, 99–166 (1990).

A. N. Safonov, V. M. Tarasenko, A. F. Baskov, et al., "Effect of the initial structure on the strengtheneing of steel ShKh15 in treatment with CO2-laser radiation," Metalloved. Term. Obrab. Met., No. 4, 5–9 (1985).

S. A. Fedosov and A. N. Pavlov, "Investigation of the structure of steel ShKh15 after pulsed laser treatment," in: Physical Problems of Impulsive Treatment of Metals and Alloys, Kuibyshev (1988), pp. 58–66.

M. E. Blanter, Theory of Heat Treatment [in Russian], Metallurgiya, Moscow (1984).

G. T. Nazarenko, and N. P. Panchenko, "The contact fatigue strength of steel ShKh15 in dependence on the structural transformations during grinding," in: Content Strength of Engineering Materials [in Russian], Nauka, Moscow (1964), pp. 131–140.

Additional information

V. D. Kalmykov Taganrog Institute of Radio Engineering. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 13–17, July, 1992.

Rights and permissions

About this article

Cite this article

Shul'ga, A.A. Electron-beam treatment of bearing steels. Met Sci Heat Treat 34, 446–451 (1992). https://doi.org/10.1007/BF00774904

Issue Date:

DOI: https://doi.org/10.1007/BF00774904