Summary

-

1.

An addition of 30 wt.% carbonyl nickel to chromium powder may be recommended for the production of high-porosity parts from material based on reduced chromium, which are ductile at room temperature.

-

2.

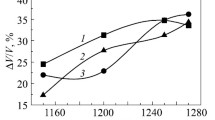

The influence of composition on the volume shrinkage of sintered mixtures of Cr and Ni powders has been established. The maximum shrinkage occurs at 35–37% Ni.

Similar content being viewed by others

Literature cited

I. M. Fedorchenko and S. M. Solonin, Poroshkovaya Met., No. 11, 26 (1965).

S. M. Solonin, Yu. M. Solonin, and V. V. Skorokhod, Poroshkovaya Met., No. 10 (1966).

U. Matsunaga, Japan Nickel Review,1, 347 (1933).

V. I. Trefilov, Collection: Physical Nature of the Brittle Fracture of Metals [in Russian], Kiev, “Naukova Dumka”, p. 22 (1965).

C. Holtz Frederick, Ductilizing brittle metals, Midwest Engr., 15, No. 6, 16 (1963).

S. M. Solonin and L. V. Globa, Poroshkovaya Met., No. 1, 13 (1965).

B. Ya. Pines and I. I. Sukhinin, Zh. Tekhn. Fiz.,26, 9, 2100 (1956).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 8(56), pp. 17–21, August, 1967.

Rights and permissions

About this article

Cite this article

Fedorchenko, I.M., Solonin, S.M. Sintering and properties of powder metallurgical chromium-base materials. Powder Metall Met Ceram 6, 612–615 (1967). https://doi.org/10.1007/BF00774545

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774545