Summary

Strongly conglomerated molybdenum powder may be produced by reducing molybdenum oxides in hydrogen by the following two methods.

-

1)

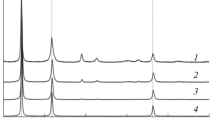

Reduction of coarse-grained molybdenum dioxide in humid hydrogen in a furnace with moving boats at a temperature of 900°C. In this case, the yield of the middle fraction of conglomerates (particles −71 + 40μ in size) having a bulk density of 1.04 g/cm3 and the same purity as grade MCh powder is about 33%.

-

2)

Reduction of coarse-grained molybdenum dioxide with dried hydrogen in a stationary muffle furnace at 1400–1500°C for 5–6 hours. The yield of conglomerates −71 + 40μ in size, with a bulk density of 1.77–2.14 g/cm3, attains 35%; this may be increased by 10–12% by crushing the coarse fraction of conglomerates.

Similar content being viewed by others

Literature cited

G. A. Meerson and A. N. Zelikman, Metallurgy of Rare Metals [in Russian] (Moscow, Metallurgizdat, 1955).

C. J. Smithells, Tungsten [Russian translation] (Moscow, Ferrous and Nonferrous Metallurgy Press, 1958).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Koryakin, I.V., Bobkova, N.N. Conditions of preparation of conglomerated molybdenum powder. Powder Metall Met Ceram 3, 109–112 (1964). https://doi.org/10.1007/BF00774479

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774479