Summary

-

1.

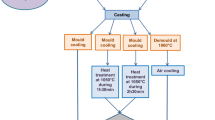

Two techniques were developed for the production of large niobium carbide parts, such as furnace heating elements and shields. The first technique, based on the use of phenolformaldehyde resin, may be recommended for the manufacture of high-porosity carbide parts with increased carbon contents, and the second, consisting of the molding of dry carbide powders, for the manufacture of low-porosity parts containing practically no free carbon.

-

2.

Niobium carbide rod-type heating elements were tested in high-temperature resistance furnaces.

-

3.

Tests were made on the LTs-42 experimental industrial high-temperature induction vacuum furnace with niobium carbide heating elements and shields. The furnace design is based on that of the OKB-530 furnace (constructed at VNIIÉTO). The height of the working space is 1.3 m, and the internal diameter is 0.25 or 0.18 m.

-

4.

It is shown that the operating temperature of furnaces with graphite heating elements may be raised by applying carbide coatings or using niobium carbide shields.

.

Similar content being viewed by others

Literature cited

R. Kieffer and P. Schwarzkopf, Hard Alloys [Russian translation], Moscow, Metallurgizdat (1957).

L. Holland, Vacuum,6, 161 (1959).

P. S. Kislyi, A. D. Panasyuk, and G. V. Samsonov, Poroshkovaya Met., 2, 38 (1962).

A. I. Avgustinik, V. Sh. Vigdergauz, V. M. Gropyanov, and G. V. Drozdetskaya, Poroshkovaya Met., 6, 11 (1963).

O. P. Kolchin, N. V. Sumarokov, and I. K. Berlin, Sb. Nauchn. Tr. Giredmeta, 1, 712 (1959).

R. Fries, Vaporisation behavior of niobium carbide, J. Chem. Phys.,7, 2, 320 (1962).

O. P. Kolchin, Sb. Nauchn. Tr. Giredmeta, 6, 56 (1962).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kolchin, O.P., Berlin, I.K. Manufacture and applications of niobium carbide components. Powder Metall Met Ceram 4, 281–287 (1965). https://doi.org/10.1007/BF00774338

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774338