Conclusions

A study was made of the possibility of preparing copper powder by the method of reduction by titanium compounds in aqueous solutions, and it was established that, as a result of the reaction of titanium sulfate Ti2(SO4)3 with copper sulfate CuSO4 in a solution with an addition of 200–250 g/dm3 I2SO4, a very fine, pure copper powder with rounded particles is produced.

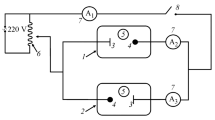

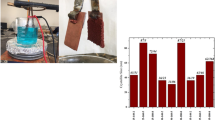

Two methods of preparing copper powder were developed: one employing the gradual addition (drop by drop) of a saturated CuSO4 solution to a Ti2(SO4)3 solution (periodic method) and another employing the anodic dissolution of metallic copper in a Ti2(SO4)3 solution (continuous method). In both cases, the process is carried out with the simultaneous electrochemical reduction Ti4++e→Ti3+ on a lead or copper cathode.

The periodic method is more suitable for the preparation of powders of extra-high purity, because it is easier to remove impurities from salts than from metals. The advantages of the continuous method comprise the possibility of utilizing various forms of copper scrap as anodes, absence of losses of titanium and copper salts, and possibility of performing the process automatically.

The following have been developed: a procedure for the treatment and drying of powder, and methods of determining powder size and the degree of purity of the product. It is shown that, for determining the degree of oxidation of copper powder, it is possible to use a visual method of comparing the color of the product with that of specially prepared reference specimens.

Similar content being viewed by others

Literature cited

B. A. Borok, M. Yu. Bal'shin, and N. A. Gavrilova, Zhur. NIIMASH, 4 (1935).

O. A. Esin and L. G. Levian, Trudy Ural'sk. Indust. Inst., 24 (1947); A. I. Levin, Trudy Ural'sk. Indust. Inst., 24 (1947).

A. Calusary, Prepararea electrolitica apulberii de cupru, Pev. Chim.,8, No. 5, 369 (1957).

A. Rahman and T. Khundkar, Electrodeposition of copper powder, Pakistan, J. Sci.,6, No. 1, 1 (1954).

É. M. Natanson, Colloidal Metals [in Russian], Kiev, Acad. Sci. Ukr. SSSR Press (1959).

T. Craig and J. Spence, English patent No. 6161 (1912).

N. N. Tsyurupa and A. I. Shutova, Trudy MKhTI im. Mendeleeva, 19 (1954); Khim. Prom., 3 (1961).

E. V. Alekseevskii, R. K. Gol'ts, and A. P. Musakin, Quantitative Analysis [in Russian], Moscow, Goskhimizdat, p. 365 (1957).

A. I. Levin, A. V. Pomosov, V. S. Kolevatova, et al., in Collection: Corrosion and Metallic Coatings [in Russian], Urals Engng. Inst., Moscow, Mashgiz (1953).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kudryavtsev, N.T., Mikhailov, N.I. & Novikov, A.A. The production of very fine copper powder. Powder Metall Met Ceram 2, 190–194 (1963). https://doi.org/10.1007/BF00774271

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774271