Summary

-

1.

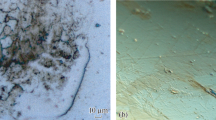

On the basis of an analysis of the stress versus strain diagrams of reduced iron sintered in hydrogen at 1473 °K for 2 h, with porosities of 10, 20, 30, 40, and 50%, new relationships were obtained, showing the effect of porosity in the plastic region on uniformly distributed elongation and reduction of area, as well as Poisson's ratio, as calculated from these magnitudes.

-

2.

The ductility characteristics of porous iron depend strongly on surface condition. By employing oxidation, it is possible to double the yield stress of porous iron of 38.8% porosity and reduce its ductility by a factor of 5. The resultant strength change does not exceed 10%.

-

3.

The modulus of elasticity of porous iron depends on the magnitude of prior plastic deformation. For this reason, the contact cross section, determined as the ratio of the moduli of elasticity of the porous and dense materials, only approximately characterizes the cross section along which fracture takes place.

Similar content being viewed by others

Literature cited

A. Ya. Krasovskii, Poroshkovaya Met., No. 4 (1964).

I. M. Fedorchenko, V. G. Filimonov, and M. G. Grabino, Vestn. Mashinostr., No. 8, 35 (1947).

V. T. Troshchenko, Collection of Papers at Conference on Statistical Strength Methods in Engineering [in Russian] (VINITI, Moscow-Leningrad, 1964).

V. A. Kuz'menko, Sonic and Ultrasonic Vibrations [in Russian] (Izd. UkrSSR, Kiev, 1963).

N. A. Filatova, Collection: Machine and Instrument Construction [in Russian] (Masprom, Kiev, 1958), No.10–11.

I. N. Frantsevich, I. D. Radomysel'skii, I. M. Fedorchenko et al., Collection: Powder Metallurgy [in Russian] (Moscow, 1954).

E. N. Andrade, Properties of Metallic Surfaces, Rep. Inst. of Metals, No. 13 (London, 1953).

V. I. Likhtman, P. A. Rebinder, and G. V. Karpenko, Effect of Surface-Active Environment on Metal Deformation Processes [in Russian] (Izd. AN SSSR, 1954).

V. I. Likhtman, E. D. Shchukin, and P. A. Rebinder, Physicochemical Mechanics of Metals [in Russian] (Izd. AN SSSR, Moscow, 1963).

I. M. Fedorchenko, G. G. Gnesin, and R. A Andrievskii, Collection: Powder Metallurgy [in Russian] (Yaroslavl', 1957).

M. Yu. Bal'shin, DAN SSSR,67, 831 (1949).

M. Yu. Bal'shin, Poroshkovaya Met., No. 4, 29 (1963).

M. Yu. Bal'shin, Powder Metallography [in Russian] (Metallurgizdat, Moscow, 1948).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Krasovskii, A.Y. Some regularities of the deformation and rupture of porous sintered iron-base materials. II. Powder Metall Met Ceram 3, 360–365 (1965). https://doi.org/10.1007/BF00774233

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774233