Summary

-

1.

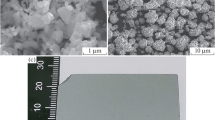

It was shown to be possible to obtain shaped articles from powders of TiC by casting.

-

2.

The best suspension agent proved to be 2.5% water solution of carboxymethyl cellulose. The best casting properties in the slip were obtained with a solids-liquid ratio of 70∶30 and 67∶33.

-

3.

Increasing the temperature of the mold and slip to 50° increases the density of the casting and the rate of casting.

-

4.

Change in pH by adding HCl and NaOH to the slip, does not improve its casting properties. In connection with this, the method was simplified since it does not require pH control.

-

5.

Density of the slip-cast articles is located within the limits which are obtained by other methods of fabrication. Uniform packing of the particles over the whole cross section of the casting gives certain advantages to this method.

-

6.

Articles obtained by slip casting are sintered with a high but uniform shrinkage, and ensure the production of articles with the porosity of 11%.

Similar content being viewed by others

Literature cited

P. Chiotti, Iowa State College Sci.,26, 185 (1958).

German patents No. 231231 and 234446 (1910).

P S. Kislyi and G. V. Samsonov, Izv. AS, USSR OTN series “Metallurgy and Fuels” No. 6, 133 (1959).

G. V. Samsonov, Properties of Refractory Compounds (Short handbook), Moscow (1961), 314.

O. Meyer, Ber. dtsch. chem. Ges.,11, 333–63; Arch. für. Eisenhuttenwesen,4, 193–98 (1930).

A. Williams, Metal Treatment,18, 445–49 (1951).

E. M. Grala, Powder Metallurgy, Ed. by Werner Liszynsky, 507–524, New York-London (1961).

T. Vasilos and W. Kingery, J. Phys. Chem. (June, 1954).

V. K. Veber, Cermets, edited by D. Tinklipo, Foreign Literature Press, Moscow (1962), 97.

M. Sivachek, Poroshkovaya Metallurgiya, No. 5, 34 (1964).

A. D. Panasyuk and P. S. Kislyi, Poroshkovaya Metallurgiya, No. 4, 18 (1965).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dobrovol'skii, A.G., Popichenko, E.Y. Slip casting of titanium carbide components. Powder Metall Met Ceram 4, 731–736 (1965). https://doi.org/10.1007/BF00774221

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774221