Summary

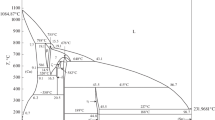

The principal diffusion constants of carbon — the preexponential factor D0 and the energy of activation of the process, Q — have been determined with the aid of the isotope C14.

As a result of annealing for 3.5 h in the temperature range 1100–1450°C, carbon was found to penetrate into tungsten and molybdenum to depths of 5 and 40 μ, respectively.

Similar content being viewed by others

Literature cited

G. V. Samsonov and G. V. Latysheva, Dokl. Akad. Nauk SSSR,109, 582 (1956).

M. Pirani and I. Sandor, Journ. Institute of Metals,73, 385, (1947).

I. A. Becker, E. I. Becker, and R. G. Brandes, J. App. Phys.,32, 3, 411 (1961).

G. V. Samsonov and A. P. Épik, Fiz. Metal i Metalloved.,14, 63, 479 (1962).

A.N. Zelikman, Metallurgy of Tungsten and Molybdenum [in Russian] Moscow, Metallurgizdat, (1949).

A. H. Cottrrell, Usp. Fiz. Metal.,1, 155 (1956).

L. N. Aleksandrov, Zavodsk. Lab.,8, 975 (1960).

N. G. Gusev, Handbook of Radioactive Radiations and Protection [in Russian] Moscow, Medgiz, (1956).

L. N. Aleksandrov and V. Ya. Shchelkonogov, Uch. zap. Mordovsk. Gosuniv.,18, 39 (1961).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Aleksandrov, L.N., Shchelkonogov, V.Y. The diffusion of carbon into tungsten and molybdenum at low carbon concentrations. Powder Metall Met Ceram 3, 288–291 (1964). https://doi.org/10.1007/BF00774172

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774172