Conclusions

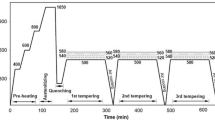

Steel D7KhFNSh is suitable for manufacturing parts operating under conditions of compression. The best combination of mechanical properties in compression is obtained by oil quenching from 840° and tempering at 170–200°.

Similar content being viewed by others

Literature cited

V. N. Vinogradov, G. M. Sorokin, and G. K. Shreiber, Impact-Abrasive Wear of Milling Cutters [in Russian], Nedra, Moscow (1975), p. 168.

Ya. B. Fridman, Mechanical Properties of Metals [in Russian], Vol. 2, Mashinostroenie, Moscow (1974), p. 368.

G. M. Sorokin and S. N. Bobrov, "Effect of tempering temperature on the fatigue strength of high-strength tool steel," Metalloved. Term. Obrab. Met., No. 9, 30 (1974).

S. N. Bobrov and L. N. Turov, "Wear and failure of the teeth of milling cutters made from uncarburized steel," Mashiny i Neftyanoe Oborudovanie, No. 5, 14 (1973).

Additional information

I. M. Gubkin Moscow Institute of the Petrochemical and Gas Industry. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 48–49, June, 1978.

Rights and permissions

About this article

Cite this article

Bobrov, S.N. Effect of tempering temperature on the mechanical properties of high-strength tool steel. Met Sci Heat Treat 20, 479–480 (1978). https://doi.org/10.1007/BF00773993

Issue Date:

DOI: https://doi.org/10.1007/BF00773993