Conclusions

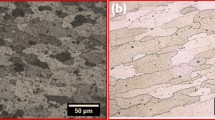

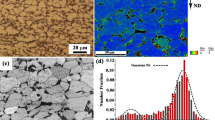

The martensitic base of the surface hardened layer is inhomogeneous in phase composition. Despite complicating concepts post-hardening tempering does not cause homogenization of the martensitic phase. Decomposition of the martensite has a heterogeneous character. In the hardened layer and the transition zone together with the low-carbide constituent there is formed a high-carbon one. The presence of high-carbon α-martensite may not inpoint of concepts on homogeneous martensite, the degree of tetragonality of which is close to unity, it is difficult to explain the phenomenon of high hardness of rolling mill rolls. Undoubtedly the high-carbon constituent is one of the factors causing an increase in hardness in tempering of type 9KhMF steel. The two martensites manifest themselves differently in rolling. Concepts of the heterogeneous nature of maratensite may be used for improving the service conditions of rolling rolls.

Similar content being viewed by others

Literature cited

B. A. Brusilovskii, V. N. Zaika, and T. E. Piskareva, "An investigation of residual austenite in the surface layer of cold rolling rolls", Fiz. Met. Metalloved.,67, No. 6, 1134–1137 (1989).

B. A. Brusilovskii "A study of the decomposition of martensite by the simulation method", Fiz. Met. Metalloved.,16, No. 3, 361–365 (1963).

B. A. Brusilovskii and F. I. Ivanov "An x-ray diffraction investigation of low-temperature tempering of cold rolling rolls". Fiz. Met. Metalloved.,19, No. 1, 147–150 (1984).

M. E. Blanter, The Theory of Heat Treatment [in Russian], Metallurgiya, Moscow (1984).

A. I. Kondrashov, V. A. Kamalov, and K. F. Gruzhienko, "Improving the heat treatment production operation of cold rolling rolls", in: Forging and Heat Treatment No. 5, Tsent. Inst. Nauch.-Tekh. Inf. Mashinostr., Leningrad (1959), pp. 70–82.

B. A. Brusilovskii, V. K. Zabolotskii, and F. I. Ivanov, "A method of determination of the degree of tetragonality of the martensite of hardened steel", Zavod. Lab., No. 1, 27–29 (1976).

Yu. A. Geller and A. G. Rakhshtadt, Material Science [in Russian], Metallurgiya, Moscow (1975).

Additional information

Kramatorsk Industrial Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 10–12, February, 1991.

Rights and permissions

About this article

Cite this article

Brusilovskii, B.A., Shashko, A.Y. Structural condition of martensite in the surface layer of cold rolling rolls. Met Sci Heat Treat 33, 100–103 (1991). https://doi.org/10.1007/BF00773881

Issue Date:

DOI: https://doi.org/10.1007/BF00773881