Conclusions

-

1.

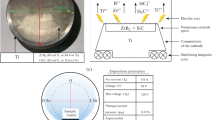

Plasma deposition of zirconium, and niobium carbides should be performed in a gaseous medium with an oxygen percentage lower than 0.3% by volume, using particles with a mean size of 30 μm.

-

2.

For niobium carbide, the maximum attainable composition in plasma vaporized coating is NbC0.8.

-

3.

For zirconium carbide, the maximum composition achieved in our experiments was ZrC0.9; however, there is no obstacle in principle to achieving a ZrC composition.

-

4.

The percentage of free carbon in the vaporized coating of carbides is reduced by about one half.

Similar content being viewed by others

Literature cited

M. N. Usov and A. I. Borisenko, Use of Plasma for the Production of High-Temperature Coatings [in Russian], Izd-vo “Nauka,” Moscow-Leningrad (1965).

C. Urban, Bull. Soc. Fr. Ceram.,72, 4 (1964).

D. R. Mash, J. of Metals,7 (1961).

A. R, Stetson, J. of Metals,7 (1961).

M. A. Levinstein, Met. Finish. Journal,6, 72 (1960).

S. Yu. Sharivker, Élektronnaya Obrabotka Mat., No. 2 (8) (1966).

L. I. Mirkin, Manual of X-Ray Structural Analysis of Polycrystals [in Russian], Fizmatgiz (1961).

A. E. Koval'skii and T. G. Makarenko, in: Microhardness [in Russian], Izd-vo. AN SSSR., Moscow (1951), p. 187.

G. V. Samsonov, A. L. Burykina, L. V. Strashinskaya, and É. A. Pugach, Izv. Akad. Nauk SSSR, Metal-lurgiya i Gornoe Delo, No. 4 (1964).

G. V. Samsonov, High-Melting Compounds [in Russian], Metallurgizdat, Moscow (1963).

V. L. Derkach, Yu. G. Yasnitskii, and I. I. Gol'danskaya, Vestnik Kievsk. Politekhn. Inst., Seriya Methaniko-Tekhnologich., No. 2 (1965).

T. Ya. Kosolapova, V. B. Fedorus, and Yu. B. Kuz'ma, Izv. Akad. Nauk SSSR, Neorgan, Mat.,2, No. 8 (1966).

A. S. Bolgar, V. V. Fesenko, and O. T. Khorpyakov, Vaporization of niobium and tantalum carbides, Inf. Lis'mo IPM AN, Ukr.SSR, No. 40, Kiev (1966).

A. S. Bolgar, V. V. Fesenko, and O. T. Kharpyakov, “High-temperature vaporization of titanium, zir-conium, and hafnium carbides,” Inf. Lis'mo IPM AN Ukr.SSR, No. 9, Kiev (1966).

G. V. Samsonov and Ya. S. Umanskii, Hard Compounds of High-Melting Metals [in Russian], Metal-lurgizdat, Moscow (1957).

A. I. Avgustinik, V. M. Gropyanov, G. V. Drozdetskaya, and V. Sh. Vigdergaus, Ogneupory, No. 12 (1964).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 12 (72), pp. 74–81, December, 1968.

Rights and permissions

About this article

Cite this article

Sharivker, S.Y., Olievskii, M.I. Behavior of zirconium and niobium carbides in plasma. Powder Metall Met Ceram 7, 989–994 (1968). https://doi.org/10.1007/BF00773438

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00773438