Conclusions

-

1.

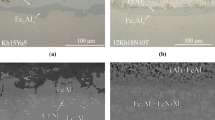

Increase of atmosphere corrosivity and operating temperature for components with heat-resistant aluminide coatings leads to an increase in the role of phase instability in coating failure.

-

2.

Diffusion processes occuring during operation cause impoverishment of the β-phase (NiAl) of aluminosilicide coatings in alloying elements and its destabilisation.

-

3.

Aluminosilicide coatings on alloys with a high chromium content may be used effectively in a corrosive gas atmosphere with retention at temperatures which do not lead to martensitic transformation.

-

4.

Co−Cr−Al-Y coatings compared with Al−Si and Al−Nb−Si coatings have a greater stability and better corrosion resistance during operation in combustion products with a high sulfur content.

Similar content being viewed by others

Literature cited

P. T. Kolomytsev, Heat-Resistant Diffusion Coatings [in Russian], Metallurgiya, Moscow (1979).

D. Kotsoradis, P. Felix, et al. (eds.), Heat-Resistant Alloys for Gas Turbines. Materials of an Internat. Conf. [Russian translation], R. E. Shalin (ed.), Metallurgiya, Moscow (1981).

V. S. Litvinov, E. G. Pantsyreva, and I. L. Kupriyanov, “Martensitic transformation in the aluminized layer of a nickel alloy”, Metalloved Term. Obrab. Met., No. 6, 71–72 (1973).

I. N. Bogachev, E. G. Lesnikova, and V. S. Litvinov, “Effect of β-phase instability of an aluminide coating on condition and operating capacity of the surface layer of a component”, in: Structural Strength of Engines. Proc. 5th All-Union Conf., Kuibyshev Aviation Inst. (1978).

Yu. G. Veksler, V. G. Sorokin, V. P. Lesnikov, et al., “Gas dynamic bench for testing high-temperature materials in liquid fuel combustion products”, Probl. Prochn., No. 4, 6–10 (1978).

B. A. Movchan and I. S. Malashenko, “Use of electron-beam evaporation for preparing heat-resistant coatings”, in: High-Temperature Protection of Materials [in Russian], Nauka, Leningrad (1981).

R. Kollong, Nonstoichiometry [Russian translation] (F. M. Spiridonova, editor B. I. Pokrovskii), Mir, Moscow (1974).

V. A. Movchan, I. S. Malashenko, and G. A. Pap, “Study of the structure and properties of condensed Co−Cr−Al−Y alloys obtained by electron-beam evaporation in a vacuum”, Probl. Spets. Elektrometallurgii, No. 8, 78–87 (1978).

C. T. Sims and W. C. Hagel (eds.), The Superalloys, Wiley (1972).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 45–50, April, 1987.

Rights and permissions

About this article

Cite this article

Veksler, Y.G., Lesnikov, V.P., Paleeva, S.Y. et al. Structural transformations in heat-resistant protective coatings on nickel alloys. Met Sci Heat Treat 29, 302–307 (1987). https://doi.org/10.1007/BF00769431

Issue Date:

DOI: https://doi.org/10.1007/BF00769431