Conclusions

-

1.

The optimum properties of masks may be obtained with tann=770–820°C, and regardless of chemical analysis of the steel and the conditions of preliminary cold rolling the minimum tensile strength and coercive force, the maximum ferritic grain size, and the sharpest crystallographic structure, providing good formability of the strip, are provided.

-

2.

A reduction in carbon content from 0.05 to 0.004% under otherwise similar conditions leads to a reduction in tensile strength of 7–10 N/mm2, in coercive force of 20–25 A/m, and in microhardness of 3–5 N and an increase in the P(111)/P(100) ratio of 2–3 relative units with a reduction in elongation on the area of flow of 2–3%.

-

3.

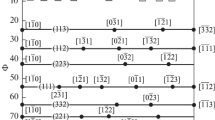

The use in production of the strip of double cold rolling with an intermediate anneal in the production line with a second rolling with ε=29% has a significant influence on the properties of the finished masks. In comparison with single rolling the tensile strength drops by 50 N/mm2, the coercive force by 50 A/m, and the microhardness by 5–8 N while the average grain size increases by not less than twice and the P(111)/P(100) ratio by five to six times.

-

4.

Use of double cold rolling of strip and annealing of the masks at 770–820°C but not above the Ac3 provides an approximately 20% reduction in scrap for nonuniform transparency and tear defects in spherization.

Similar content being viewed by others

Literature cited

V. Hasek, "Untersuchung und theoretische Beschreibung wichtiger Einflusgrösen auf das Grenzformänderungsschaubild," Blech-Rohre-Profile, No. 5, 213–220 (1978).

D. Blickwede, "Steel sheets per millions," Trans. Quarterly,61, No. 4, 653–679 (1968).

A. A. Vostrikov, V. P. Gubchevskii, and E. D. Nemkina, "Formation of textures in deformation of low-carbon steel," Fiz. Met. Metalloved.,35, No. 4, 832–836 (1973).

R. U. Kan (ed.), Physical Metallurgy [in Russian], Vol. 3, Metallurgiya, Moscow (1987).

J. M. Michalak and R. D. Shoone, "Texture recrystallization of cold rolled steel sheet," Trans. Met. Soc. AIME,242, No. 6, 1149–1160 (1968).

Additional information

Magnitogorsk Metallurgical Combine. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 44–47, March, 1991.

Rights and permissions

About this article

Cite this article

Gubchevskii, V.P., Frolov, A.P., Nemkina, É.D. et al. Influence of heat treatment on the properties of cold-rolled precision carbon strip. Met Sci Heat Treat 33, 244–249 (1991). https://doi.org/10.1007/BF00769354

Issue Date:

DOI: https://doi.org/10.1007/BF00769354