Conclusions

-

1.

When a microalloying combination in chromium hard-faced metal consisting of ≤0.02% Al; 0.013% Y; and ≤0.05% Zr is used, the non-metallic inclusion particle size decreases and their volume fraction increases. The decrease in the size of the NI leads to a decrease in the mean grain size.

-

2.

With the decrease in the size of the NI, there is a decrease in the plastic deformation zone around the inclusions and a corresponding decrease in the tendency of the hard-faced metal to form cracks.

-

3.

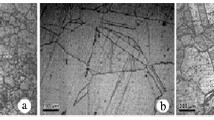

The sulfides which form a film along the grain boundaries in chromium hard-faced metal act as initiation sites for the formation of the first microcracks in the presence of thermal cycling under a tensile load. After modification and microalloying of the hard-faced metal, ring-like microspaces form around the globular sulfides and oxides at the grain boundaries, which do not develop into microcracks.

-

4.

Under thermal cycling conditions, the NI become smaller in size, globular, and dispersed. These factors act to decrease the negative effect of NI as sources for the initiation of microcracks in chromium hard-faced metals.

Similar content being viewed by others

Literature cited

V. S. Ivanova, S. E. Gurevich, I. M. Kon'ev, et al., The Fatigue and Strength of Metallic Materials [in Russian], Nauka, Moscow (1968).

A. G. Aleksandrov, I. P. Volchok, M. V. Lutov, et al., "The effect of calcium, yttrium, and cerium on the structure and properties of hard-faced metals," Avtomat. Svarka, No. 1, 40–42 (1977).

V. I. Yavoiskii, Yu. I. Rubenchik, and A. P. Osenko, Non-Metallic Inclusions and the Properties of Steel [in Russian], Metallurgiya, Moscow (1980).

B. B. Yarovoi, B. A. Klypyn, and V. I. Polikarpov, "Oxides and nitrides in steel 12Kh1MF containing microalloyed zirconium", in: Methods and Means for Controlling the Quality of Ferrous Alloys [in Russian], Metallurgiya, Moscow (1984), pp. 70–73.

I. Artinger, Handbook of Tool Steels and Their Heat Treatment [Russian translation], Metallurgiya, Moscow (1982).

D. Mak-Lin, Grain Boundaires in Metals [Russian translation], Metallurgizdat, Moscow (1960).

Kh. I. Shpis, The Behavior of Non-Metallic Inclusions in Steel during Crystallization and Deformation [Russian translation], Metallurgiya, Moscow (1971).

M. B. Movchan and V. A. Efimov, "The mechanism of by which the initial structure of cast alloys is modified by dispersion of the nonmetallic particles," Izv. AN SSSR, Metall., No. 4, 109–116 (1984).

G. A. Buryakovskii and R. D. Mininzon, Surface Defects in Alloy Steels [in Russian], Metallurgiya, Moscow (1987).

V. V. Podgaitskii and G. I. Parfesso, Sulfide Induced Welding Cracks [in Russian], Naukova Dumka, Kiev (1977).

T. M. Slutskaya, A. A. Aenis, and A. Ya. Tyurin, "The properties of wires alloyed with yttrium and cerium during welding in CO2", Avtomat. Svarka, No. 2, 55–56 (1978).

V. F. Musyachenko, I. S. Mel'nik, M. B. Movchan, and B. M. Kir'yakov, "The effect of rare earth metal additions used to modify nonmetallic inclusions on the structure and properties of weld joints using high strength steels", Avtomat. Svarka, No. 6, 1–6 (1987).

M. P. Braun, Microalloyed Steels [in Russian], Naukova Dumka, Kiev (1987).

G. S. Mikaelyan, N. L. Kareta, G. N. Gordan', et al., "The effect of yttrium on the properties of chromium hard-faced metals", Avtomat. Svarka, No. 12, 16–18 (1987).

F. Hegerer and L. Kvist, Harterei-Technische Mittunden,70, No. 2, 91–99 (1975).

G. A. Byalik, E. M. Tsivirko and V. I. Gontarenko, "The effect of nonmetallic inclusion hardness on stress state development in steel ShKh15" in: Techniques in Thermal Microscopy [in Russian], Nauka, Moscow (1976), pp. 138–140.

V. M. Finkel', O. P. Elesina, and B. A. Zraichenko, "Non-metallic inclusions and the strength of steel", Dokl. Akad. Nauk SSSR,183, No. 3, 576–579 (1968).

Additional information

E. O. Paton Electrowelding Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 23–25, March, 1991.

Rights and permissions

About this article

Cite this article

Mikaelyan, G.S., Novikova, D.P. High-temperature failure resistance of a chromium hard-faced metal. Met Sci Heat Treat 33, 206–211 (1991). https://doi.org/10.1007/BF00769344

Issue Date:

DOI: https://doi.org/10.1007/BF00769344