Conclusion

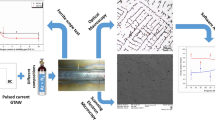

Induction heat treatment of corrosion-resistant steel pipes in the line of an argon-arc welding mill produces a fine-grain structure of the base metal and weld, ensures the mechanical properties of pipes as specified in GOST 11068-81: σt ≧ 560 N/mm2; δ5 ≧ 36%. and also makes possible the oxidation of the metal by 0.33%, reduces the time and consuption of the etching solution during chemical processing, and saves power.

Similar content being viewed by others

Literature cited

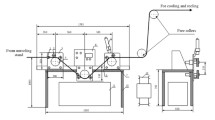

A. A. Shkurenko, V. P. Orlov, M. S. Rossinskii, et al., "Machine for induction heating of pipes in the line of an argon-arc welding mill," Byull. Chernaya Metall.,981, No. 1, 45–46 (1985).

Additional information

Dnepropetrovsk, Moscow Pipe Works. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 26–29, August, 1987.

Rights and permissions

About this article

Cite this article

Zgura, A.A., Krichevskii, E.M., Rudenko, V.A. et al. Heat-treatment with induction heating of pipes within the pipe welding mill. Met Sci Heat Treat 29, 588–591 (1987). https://doi.org/10.1007/BF00763112

Issue Date:

DOI: https://doi.org/10.1007/BF00763112