Abstract

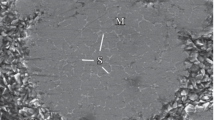

Creep in pure and two phase nickel-doped alumina has been investigated in the stress range 0.70 to 4.57 kgf mm−2 (1000 to 6500 psi), and temperature range 1450 to 1800° C, for grain sizes from 15 to 45 μm (pure alumina) and 15 to 30 um, (nickel-doped alumina). The effect of stress, grain size and temperature on the creep rate suggests that diffusion controlled grain-boundary sliding is the predominant creep mechanism at low stresses and small grain sizes. However, the stress exponents show that some non-viscous boundary sliding occurs even at the lowest stresses investigated. This mechanism is confirmed by metallographic evidence, which shows considerable boundary corrugation in the deformed aluminas. At higher stresses and larger grain sizes the localized propagation of microcracks leads to high stress exponents in the creep rate equation. The nickel dopant, which introduces an evenly distributed spinel second phase into the alumina matrix, increases the creep rate and enhances boundary sliding and localized crack propagation. The weakening effect of the second phase increases with grain size, and tertiary creep occurs at strains of 0.5% and below in large grained material.

Similar content being viewed by others

References

P. E. Evans, B. P. Hardiman, B. C. Mathur, andW. S. Rimmer,Trans. Brit. Ceram. Soc. 66 (1967) 523.

P. E. Evans,Brit. Pat. No. 1106327.

A. H. Heuer, R. M. Cannon, andN. J. Tighe, in: “Ultrafine Grain Ceramics” (eds. J. J. Burke, N. L. Reid, and Volker Weiss) Proceedings of the Fifteenth Sagamore Army Materials Research Conference (Syracuse University Press, 1970) pp. 339–365.

P. E. Evans, in: “Materials Science Research” Vol. 3 (eds. W. W. Kriegel and H. PalmourIII) (Plenum, New York, London, 1966) pp. 345–353.

A. Crosby, Ph.D. Thesis, Manchester University (1971).

Anne-Marie Lejus, Thesis, Faculté Des Sciences de l'université de Paris (1964).

P. J. Jorgensen andJ. H. Westbrook,J. Amer. Ceram. Soc. 47 (1964) 332.

L. E. Poteat, Ph.D. Thesis, North Carolina State University, Raleigh, N.C. (1966); Univ. Microfilms (Ann Arbor, Mich.), Order No. 66-11, 978; 264 pp.Dissertation Abstr. B,27 (1966) 1961.

A. E. Paladino andW. D. Kingery,J. Chem. Phys. 37 (1962) 957.

P. E. Evans,J. Amer. Ceram. Soc. 53 (1970) 365.

J. H. Hensler andG. V. Cullen,ibid 51 (1968) 557.

J. A. C. Marples andA. Hough, U.K.A.E.A. Research Group Report AERE-R6421 (1970).

E. M. Passmore andT. Vasilos,J. Amer. Ceram. Soc. 49 (1966) 166.

R. L. Coble andY. H. Guerard,ibid 46 (1963) 353.

C. Herring,J. Appl. Phys. 21 (1950) 437.

R. L. Coble,ibid 34 (1963) 1679.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Crosby, A., Evans, P.E. Creep in pure and two phase nickel-doped alumina. J Mater Sci 8, 1573–1580 (1973). https://doi.org/10.1007/BF00754892

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00754892