Abstract

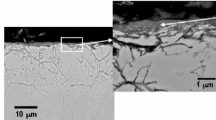

Aluminide coatings are known to protect steels from oxidation and corrosion in hydrocarbon and sulfur-bearing atmospheres. Pack cementation is ideally suited for forming these coatings on small intricate components, wherein a diffused layer is formed which is well bonded to the substrate. Even though pack aluminide coated steels are being commercially used, there has not been any systematic investigation of the factors that control the coating formation. The present investigation has been carried out to define the boundary conditions under which diffusion in the solid phase determine the coating kinetics. The effect of pack activity and temperature on the structure and kinetics of aluminde layer formation on EN-3 steel has been investigated. The coating characteristics were evaluated by metallography, EPMA, X-ray diffraction, and scanning electron microscope (SEM). Oxidation resistance of the coated samples were compared to that of 304 stainless steel after heating in air at 900°C for 72 h. The surface aluminum composition was found to be about 20% by weight which remained constant with time in the temperature range of 750°C–900°C. Weight gains and layer thicknesses obeyed parabolic relationship with time at all temperatures. Under these conditions, the system constitutes a vapor-solid diffusion couple. Interdiffusion coefficient \((\tilde D)\) values in the Fe-Al system have been determined, and the activation energy has been calculated to be 57 Kcals/mole, which agrees well with the literature values.

Similar content being viewed by others

References

W. A. Mcgill and W. J. Weinbaun, Metal Progr.115, 26 (1979).

V. R. Ryabovet al. inProtective Coatings on Metals, Vol. 3, G. V. Samsonov, ed., Eric Renner, trans. (Consultants Bureau, New York, 1971) p. 96.

V. R. Ryabov, I. Ya. Dzykovich, and V. I. Yumatova, inProtective Coatings on Metals, Vol. 5, G. V. Samsonov, ed., Eric Renner, trans. (Consultants Bureau, New York, 1973) p. 118.

B. A. Ushakov, inProtective Coatings on Metals, Vol. 5, G. V. Samsonov, ed., Eric Renner, trans. (Consultants Bureau, New York, 1973) p. 103.

N. R. Lindbald,Oxid. Met. 1, (1969).

C. Wagner,Acat Metall,17, 99 (1969).

R. Sivakumar and L. L. Seigle,Met. Trans. A,7A, 1073 (1976).

M. Hansen and K. Anderko,Constituion of Binary Alloys (McGraw-Hill New York (1958).

L. N. Larikov, V. M. Fal chenko, D. F. Polishchuk, V. R. Ryabov, and A. V. Lozovskaya, inProtective Coatings on Metals Vol. 3, G. V. Samsonov, ed. Eric Renner, trans. (Consultants Bureau, New York, 1971) p. 66.

R. Sivakumar and L. L. Seigle,Trans. Ind. Inst. Met. 31, 336 (1978).

C. J. Smithhells and E. A. Brandes,Metals Reference Book, 5th ed. (Butterworth & Co., London, 1976), p. 906.

W. E. Boggs,J. Electrochem. Soc. 118, 906 (1971).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sivakumar, R., Rao, E.J. An investigation of pack-aluminide coating on steel. Oxid Met 17, 391–405 (1982). https://doi.org/10.1007/BF00742119

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00742119