Conclusions

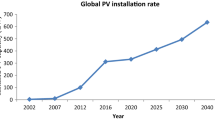

The steady increase in the production volume of machine building, metallurgy, and other sectors of the national economy from 1940 through 1980, which has raised requirements for the quality of machinery being produced, has determined the vigorous development of heating by the resistance method.

Electric resistance furnaces have continued as the most widespread form of electrothermal technology.

Basic trends in ERF development in this period are as follows:

-

a)

an increase in the unit capacities and productivity of ERF;

-

b)

a gradual increase in the proportion of continuous furnaces in the overall inventory of ERF which ensure high economy, heating accuracy and stability of the properties of the components being treated, high production regularity, and an increase in the level of mechanization;

-

c)

vigorous development of special-purpose furnaces that provide for high productivity and good quality of HT and CH during mass production with lower labor and energy outlays;

-

d)

improvement in the quality of HT and CH, and as a result of this, an increase in the output of furnaces with controlled atmospheres and vaccum furnaces;

-

e)

development of ERF to carry out HT and CH processes more effectively, and also processes that provide for the production of new materials;

-

f)

optimization of ERF parameters to reduce the cost of the HT and CH processes;

-

g)

refinement of ERF designs, including mechanization and automation, as well as the introduction of computerized control units (CCU) to control and monitor the technological HT and CH processes for the purpose of improving the technicoeconomic indicators of the electric furnaces;

-

h)

unification of ERF to reduce their cost;

-

i)

gradual improvement of vacuum ERF, including the development of highly mechanized and automated semicontinuous and continuous furnaces to operate at temperatures to 2500°C and pressures of 10−5 Pa and below;

-

j)

a systematic increase in the production and nomenclature of tubular heater elements (THE) as universal heating units for many technological processes.

Similar content being viewed by others

Additional information

Continuation (see p. 26 of the Russian original No. 5 for 1980 for the initial report).

All-Union Scientific-Research Institute for Electrothermal Treatment. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 21–27, August, 1983.

Rights and permissions

About this article

Cite this article

Shevtsov, M.A., Borodachev, A.S. Development of heating by the resistance method from 1940 through 1980. Met Sci Heat Treat 25, 582–589 (1983). https://doi.org/10.1007/BF00741919

Issue Date:

DOI: https://doi.org/10.1007/BF00741919