Abstract

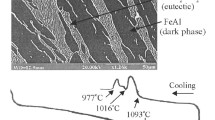

The isothermal oxidation resistance of high purity iron-manganese-aluminum alloys containing from 0 to 40% manganese and from 0 to 15% aluminum was investigated at 600, 800, and 1000°C in pure oxygen at a pressure of 200 torr for periods up to 100 hr. They were subsequently examined using SEM and metallographic techniques, and an oxide map showing the alloy structure and general oxidation behavior at 800°C was produced. Scales formed on alloys which contain insufficient aluminum to form protective alumina have structures which depend largely upon the concentration of manganese in the alloy. Alloys which contain more than 7.5% manganese form manganese rich scales, whereas alloys which contain lower levels of manganese form scales that are composed almost entirely of the oxides of iron. Small manganese oxide nodules grow through the alumina scales which form on alloys containing in excess of 9% aluminum. The most oxidation resistant alloys, having compositions within the range Fe-(5–10)%Mn-(6–10)% Al, develop continuous protective alumina scales and are totally ferritic. Austenite is detrimental to the oxidation resistance of duplex alloys as it promotes the breakdown of preexisting alumina scales and the growth of bulky manganese rich oxides. Small additions of chromium are beneficial and reduce the concentration of aluminum required to form protective alumina scales.

Similar content being viewed by others

References

P. R. S. Jackson and G. R. Wallwork,J. High Temp. Technol. 1(5), 259 (1983).

P. R. S. Jackson and G. R. Wallwork,Oxid. Metals 20, 1 (1983).

D. J. Schmatz,Trans. AIME 215, 112 (1959).

G. R. Wallwork,Rep. Progr. Phys. 39(5), (1976).

F. Saegusa and L. Lee,Corrosion 22, 168 (1966).

A. A. Krishnan and V. Prakash,J. Sci. Ind. Res. (India)13B, 444 (1954).

V. Prakash and A. A. Krishnan,J. Sci. Ind. Res. (India)15B, 600 (1956).

L. I. Shvedov and G. P. Goretskii,Izvest. Akad, Nauk Beloruss, S.S.R. (Fiz-Tekhn)1 43 (1972).

W. E. Boggs,J. Electrochem. Soc. 118(6), 906 (1971).

M. Sakiyama, P. Tomaszewicz, and G. R. Wallwork,Oxid. Met. 13(4), 311 (1979).

P. Tomaszewica and G. R. Wallwork, inProc. N.A.C.T. Conf. High Temperature Corrosion, San Deigo, Calif. (1981), p. 258.

G. C. Wood and F. H. Stott, in Ref. 11, p. 227.

R. A. Rapp,Corrosion 21, 382 (1965).

V. R. Howes,Corr. Sci. 8, 221 (1968).

G. S. Brady and H. R. Clauser,Materials Handbook, 11th ed, McGraw-Hill, New York, 1979, p. 655.

R. A. Perkins. Lockheed Palo Alto Research Laboratories, Palo Alto, Calif., Quarterly Report Fe-2299-6 (Dec. 1976.).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jackson, P.R.S., Wallwork, G.R. High temperature oxidation of iron-manganese-aluminum based alloys. Oxid Met 21, 135–170 (1984). https://doi.org/10.1007/BF00741468

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00741468