Conclusions

-

1.

Drawing and reducing of 16KhSN steel with degrees of 0–60% leads to an increase in yield strength σy from 300 to 680 MPA and in tensile strength σt from 500 to 860 MPa and a reduction in the reduction of area ψ from 72 to 57%, in the elongation δ from 30 to 9%, in the work for limiting deformation Af from 1020 to 940 MJ/m3, and in the strain-hardening factor from 0.177 to 0.080.

-

2.

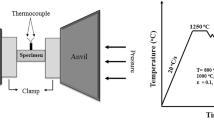

The influence of hardening heat treatment (harden from 930°C and temper at 350°C) on the mechanical properties of 16KhSN steel is similar to the influence of work hardening, but the strength properties of this steel after heat treatment increase to a greater degree than after deformation, σy to 1080 MPa, σt to 1280 MPa, and Af to 1660 MJ/m3.

-

3.

As a result of cold plastic deformation of 16KhSN steel by drawing or reducing, the density decreases (by 0.41% with degrees of deformation of ε=60%). The increase in specific volume is an indication of the "loosening" of the material in work hardening and is caused by the occurrence of submicro- and microscopic cracks and microdistortions.

-

4.

The intense decrease in plasticity of the steel in the work-hardened condition with an increase in the index of the stressed state (i.e., in the volume of the path of tension) and the increase in the notch sensitivity πψ from 0.160 to 0.575 are related to the presence of discontinuities in the structure of the material.

Similar content being viewed by others

Literature cited

P. V. Bridgman, Investigation of Large Plastic Deformations and Rupture [Russian translation], IL, Moscow (1955).

V. A. Skudnov and A. G. Kiparisov, "The question of determination of the rigidity of the stressed state in mechanical tests," in: The Production and Properties of Rolled Products from Metal Powders. Proceedings of the Gorki Polytechnic Institute [in Russian], Vol. 28, No. 8 (1972), pp. 32–38.

V. A. Skudnov, "Determination of the true strain in the neck of a specimen at rupture," Zavod. Lab.,31, No. 7, 871–873 (1965).

L. Zhil'mo, "The characteristic of the properties of structural steel in the work of limiting deformation," in: Modern Problems of Metallurgy [in Russian], Izd. Akad. Nauk SSSR (1958), pp. 572–582.

Yu. A. Gagarin, S. N. Pichkov, V. A. Skudnov, and L. D. Sokolov, "The influence of the character of the stressed state on the plasticity and fracture of structural steels," Probl. Prochn., No. 6, 70–75 (1978).

L. D. Sokalov and V. A. Skudnov, The Rules of Plasticity of Metals [in Russian], Vsesoyuz. Inst. Leg. Splav. (1980).

V. N. Gridnev, V. G. Gavrilyuk, and Yu. Ya. Meshkov, The Strength and Plasticity of Cold-Deformed Steel [in Russian], Naukova Dumka, Kiev (1974).

Yu. M. Lakhtin, The Metal Science and Heat Treatment of Metal [in Russian], Metallurgiya, Moscow (1976).

Ya. B. Fridman, The Mechanical Properties of Metals [in Russian], Vol. I–II, Mashino-stroenie, Moscow (1974).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 32–35, February, 1985.

Rights and permissions

About this article

Cite this article

Skudnov, V.A., Vorob'ev, I.A., Kutyaikin, V.G. et al. 16KhSN high-strength steel in various structural conditions and with various deformation conditions. Met Sci Heat Treat 27, 125–129 (1985). https://doi.org/10.1007/BF00736585

Issue Date:

DOI: https://doi.org/10.1007/BF00736585