Conclusions

-

1.

During induction hardening with self-tempering of main bearing journals, compressive stresses arise in the surface of the hardened layer and tensile stresses arise away from the surface.

-

2.

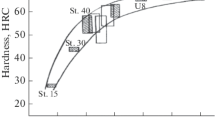

During induction hardening with a low self-temper, there is a definite ratio of the martensitic hardened layer to the total hardened thickness which causes an optimum distribution of the residual stresses: compressive stresses at the surface of the hardened layer which are close to their maximum value and tensile stresses which decrease and move toward the center of the main journal. The preferred ratio is SM:So=0.6–0.7.

-

3.

After hardening without self-tempering of the main journal, the maximum compressive stresses localize at the surface of the hardened layer and achieve values of 650–750 N/mm2. The maximum tensile stresses move deeper into the hardened layer and range in value from 450–600 N/mm2.

-

4.

At a hardened layer thickness of 2.5 mm, self-tempering at 220–250°C leads to an insignificant decrease in the tensile stresses and therefore it is not advantageous to apply hardening with low self-tempering for components which are hardened to a depth of 2.5 mm or less.

Similar content being viewed by others

Literature cited

G. F. Golovin, Residual Stresses, Strength, and Deformation after Surface Hardening using High Current Frequencies [in Russian], Mashinostroenie, Leningrad (1973).

S. A. Saltykov, Steriometric Metallography [in Russian], Metallurgiya, Moscow (1970).

F. I. Yakovlev, “Structural alignment charts of high-strength cast iron during surface hardening by induction heating”, Liteinoe Proizvod., No. 9, 11 (1983).

Additional information

Kharkov Engineering Institute of Rail Transport. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 44–46, January, 1989.

Rights and permissions

About this article

Cite this article

Yakovlev, F.I. Effect of the hardened layer thickness on the size and distribution of residual stresses in cast iron components. Met Sci Heat Treat 31, 56–59 (1989). https://doi.org/10.1007/BF00735331

Issue Date:

DOI: https://doi.org/10.1007/BF00735331