Conclusions

-

1.

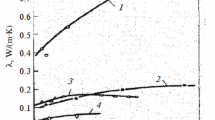

The weight loss of the materials investigated in the 300–1100°C interval ranges from 10−4 to 10−6 g/(g·sec).

-

2.

The WSS-base material begins to experience vigorous breakdown (by smouldering) on heating to 550°C, while all of the remaining carbon materials tested neigher ignite, more smoulder when air is admitted to the furnace in the 300–1100°C temperature interval (holding time of 15 min).

Similar content being viewed by others

Literature cited

É. N. Marmer, Carbon-Graphite Materials (Handbook) [in Russian], Metallurgiya, Moscow (1973).

O. S. Gurvich, Yu. P. Lyakhin, and S. I. Sobolev, High-Temperature Electric Furnaces with Graphite Elements [in Russian], Énergiya, Moscow (1974).

V. P. Sosedov (ed.), Properties of Carbon-Base Structural Materials (Handbook) [in Russian], Metallurgiya, Moscow (1975).

G. V. Grebenshchikova, M. I. Rogailin, and L. F. Koblova, “On the character of thermal transformations in carbon-fiber-reinforced plastics”, Khim. Tverd. Topliva, No. 6, 110–115 (1987).

Additional information

All-Union Scientific-Research Institute of Electrothermal Treatment. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 28–29, January, 1989.

Rights and permissions

About this article

Cite this article

Marmer, É.N., Krivoshein, D.A. & Vislobokov, V.I. Thermal-oxidizing resistance of carbon materials used in constructing vacuum resistance furnaces. Met Sci Heat Treat 31, 35–36 (1989). https://doi.org/10.1007/BF00735326

Issue Date:

DOI: https://doi.org/10.1007/BF00735326