Conclusions

-

1.

When choosing a material for the construction of a roasting oven one has to consider not only the standard properties of the refractories at hand but also their ability to slow down the desulfurization process of petroleum cokes. Ashing of the coke due to abrasive wear of the lining deteriorates the quality of the commercial coke not only with regard to ash content but also with regard to sulfur content.

-

2.

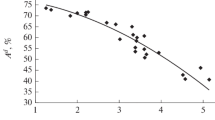

The desulfurization is slowed down even more when the ratio of alkaline to acid oxides (slag ratio) MgO+Cr2O3+CaO/Al2O3+SiO, of the refractory material is higher.

-

3.

Refractories with a high siO2 content are not suitable for coke refining ovens because the SiO2 reduces to SiO which then escapes.

-

4.

Refractories with a high Al2O3 content should be used in the construction of coke roasting ovens.

-

5.

Refractories containing magnesium, calcium, and chromium oxides and which are likely to crumble during coke refining are not suitable to line the walls of the roasting kilns in coke desulfurization plants.

Similar content being viewed by others

Literature cited

P. P. Budnikov, A. S. Berezhnoi, I. A. Bulavin, et al., Technology of Ceramics and Refractories [in Russian], Gosstroiizdat (1962).

Materials of the Temporary Commission of the State Committee for Science and Technology of the USSR for Disclosing the Possibilities of Using Sulfurous Petroleum Coke in the Electrode and Anode Industry [in Russian], TsNIItsvetmet (1960).

Z. I. Syunyaev, G. F. Ivanovskii, A. D. Sudovikov, S. A. Akhmetov, R. N. Gimaev, and Yu. M. Abyzgil'din, Problems in Processing Highly Sulfurous Petroleums [in Russian], TsNIITÉneftekhim (1966), p. 224.

A. F. Krasyukov, S. M. Slutskaya, M. I. Shepshelevich, and A. V. Tsin'ko, Problems in Processing Highly Sulfurous Petroleums [in Russian], TsNIITÉneftekhim (1966), pp. 119–126.

Z. I. Syunyaev, Upgrading and Uses of Petroleum Coke [in Russian], Izd. “Khimiya” (1966).

A. F. Krasyukov, Petroleum Coke [in Russian], Izd. “Khimiya” (1966).

M. B. Al'tman, Nonmetallic Inclusions in Aluminum Alloys [in Russian], Izd. “Metallurgiya” (1965).

F. Trojer, Radex Rundschau, No. 4–5, 189 (1956).

I. M. Galemin and A. V. Gorokh, carbon Lining in Blast Furnaces [in Russian], Izd. “Metallurgiya” (1964).

E. F. Chalykh, Roasting Kilns in the Electrode Industry [in Russian], TsNIItsvetmet (1963).

K. Wickert, Erdöl und Kohle, K,13, No. 9, 650–664 (1960).

g. F. Knorre and M. A. Kadzharov, Cyclone Furnaces [in Russian], Gosénergoizdat (1958).

D. N. Poluboyarinov, Proceedings of the Second Conference on Refractory Materials [in Russian], Izd. AN SSSR (1941), p. 163.

V. D. Tsigler, Koks i Khimiya, No. 8 (1966).

K. V. Vorob'ev and P. S. Mamykin, Proceedings of the Eastern Institute of Refractories [in Russian], Metallurgizdat (1963), pp. 233–245.

V. A. Ragoznikov et al., Ogneupory, No. 2 (1964).

“Express information,” Silikatnye Materialy, No. 23 (1960).

A. O. Al'm, Proceedings of the Second International Congress on Ceramics (Paris, 1952) [in Russian], Metallurgizdat (1962), pp. 3–15.

M. S. Makstmenko, “Ferrosilicon,” Metallurg., No. 2, 54 (1932).

Yu. M. Abyzgil'din and Z. I. Syunyaev, Neftepererabotka i Neftekhimiya, No. 7 (1967).

Z. I. Syunyaev and Yu. M. Abyzgil'din, The Chemistry of Organo-Sulfuric Compounds in Petroleum and Petroleum Products [in Russian], Vol. 9, Izd. Vysshaya Shkola (1967).

Yu. M. Abyzgil'din, The Effect of Mineral Impurities on the Process of Petroleum Coke Upgrading [in Russian], Candidate's Dissertation, Sverdlovsk (1967).

Author information

Authors and Affiliations

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 11, pp. 21–25, November, 1968.

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 11, pp. 17–21, November, 1968.

Rights and permissions

About this article

Cite this article

Abyzgil'din, Y.M., Syunyaev, Z.I. Choice of refractory materials for coke roasting. Chem Technol Fuels Oils 4, 807–810 (1968). https://doi.org/10.1007/BF00728833

Issue Date:

DOI: https://doi.org/10.1007/BF00728833